Available for Import

Available for Import

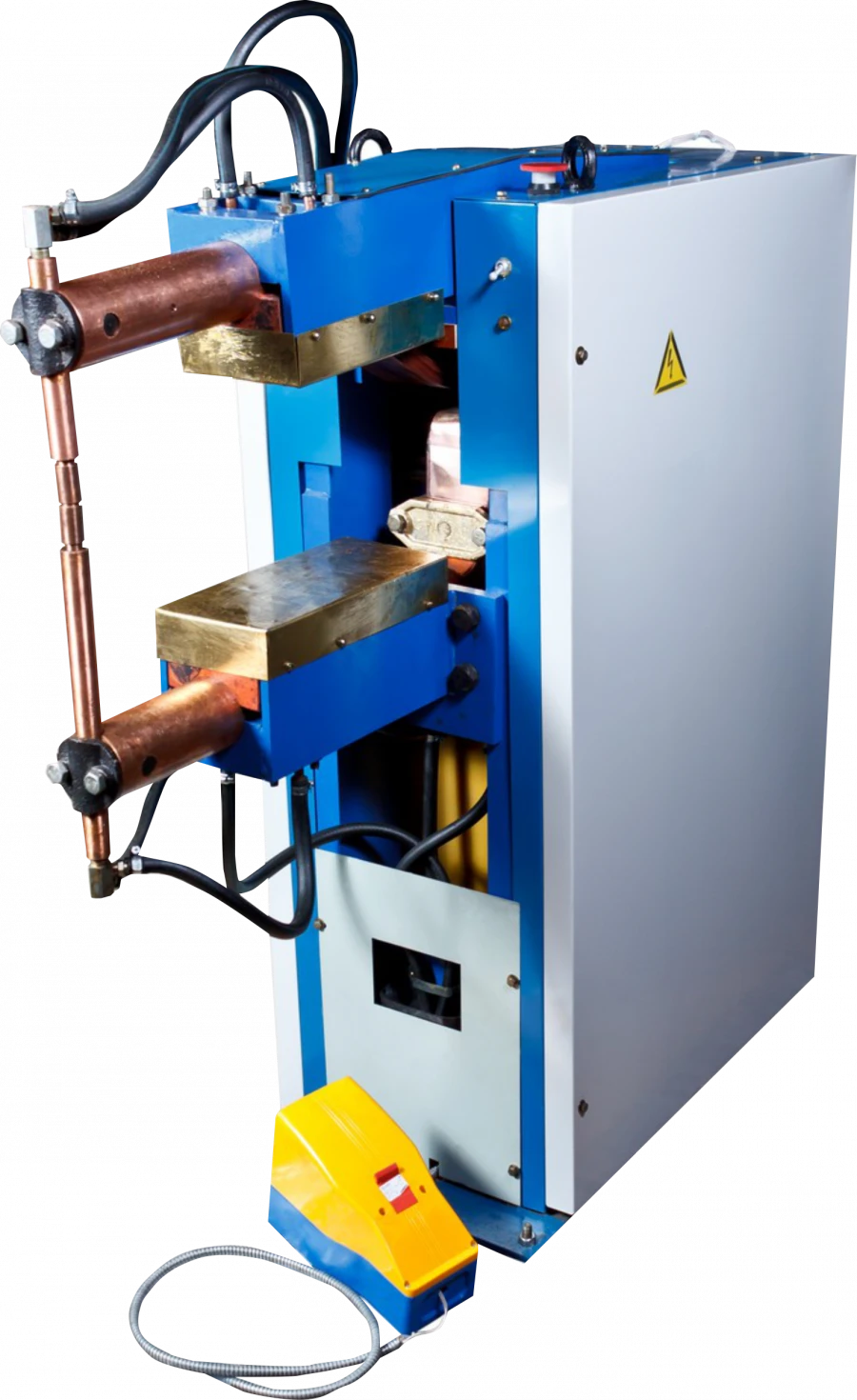

Contact welding machine MTP-2401 UHL4

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Contact welding machines are designed for electric contact spot welding of parts made of low-carbon steel sheets, for overlap welding of reinforcement of II and III class.

The machines are designed for operation in the following conditions: ambient temperature from plus 1°C to plus 35°C, ambient humidity up to 80% at 25°C, atmospheric pressure from 84.0 kPa (630 mm Hg) to 106.7 kPa (800 mm Hg); cooling water temperature from plus 5°C to plus 25°C.

Climatic version UHL - operation of machines in macroclimatic regions with temperate and cold climate.

Category 4 provides for the operation of machines in closed heated (cooled) and ventilated rooms.

Technical Specifications

| Highest secondary short-circuit current at the last stage, ±10% | 24000 A |

|---|---|

| Rated continuous secondary current | 5000 A |

| Rated power consumption (at rated step at rated current) | 82 |

| Rated welding current | 16000 A |

| Lower limit of phase current control, not more than | SBVVBG % |

| Nominal operating mode SP | 10 % |

| Nominal outreach | 500 mm |

| Shortest outreach | 350 mm |

| Maximum outreach | 1000 mm |

| Upper electrode stroke (at nominal electrode holder outreach) | 0...100 mm |

| Lowest compression force at rated outreach (at compressed air pressure in the network 98 kPa), not more than | 130 |

| Maximum compression force at minimum outreach (at compressed air pressure in the network 490 kPa), not less | 950 |

| Nominal clearance (over the most protruding parts of the lever and lower sliding arm) | 180 mm |

| Smallest dimension, not more (over the most protruding parts of the lever and lower sliding bracket), not more | 180 mm |

| The largest solution, not less (on the most protruding parts of the lever and the lower sliding arm). | 450 mm |

| Thickness of parts to be welded, hard mode | from 0,5+0,5 to 3,0+3,0 |

| Thickness of parts to be welded, soft mode | from 0,5+0,5 to 6,0+6,0 |

| Diameter of reinforcement of II and III class, not more than | 14+14 |

| Mutual displacement of electrodes at nominal compression force at nominal outreach, not exceeding | 63 mm |

| Power at SP=50%, not more | 5 |

| Highest short circuit power, not more than | 140 |

| Compressed air flow rate reduced to free state (at 200 strokes per minute) divided by the number of strokes | 6,7?10-3 |

| Length | 1315 mm |

| Width | 450 mm |

| Height | 1255 mm |

| Weight, not more | 410 kg |

| Productivity at welding of minimum thicknesses, not less than | 2343 |

| Resistance of the secondary circuit to direct current at rated outreach and solution, not more than | 85 |

| Nominal stage not lower | 3 |

| Rated compression force at nominal outreach (at mains compressed air pressure of 490 kPa) | 630 |

| Calculated cooling water flow rate | 310 |

| Maximum short-term productivity at welding of low-carbon steel with thickness of 0.5+0.5 mm, not less than | 280 |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

Welding machine ADD - 4004.6 VG I U1 North

View Details

Contact welding machine MSS-901 UHL4

View Details

Infrared soldering station IR-650 PRO "Thermopro" in COMFORT set

View Details

Welding machine ADD - 4004 VG I U1

View Details

Welding machine ADD - 4008 I U1

View Details

Aggregate for power supply of welding station ADD - 5001.1 AND U1

View Details

Apparatus for micropulse welding MOLNIA 5.0

View Details

Contact welding machine MSH-2203 UHL4

View Details

Infrared soldering station IR-650 PRO set "Optimum"

View Details

Argon arc welding unit TT573-2000

View Details

Welding rectifier VD-306 I U3

View Details

Chamber furnace for solder and solder paste melting LED-580

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions