Available for Import

Available for Import

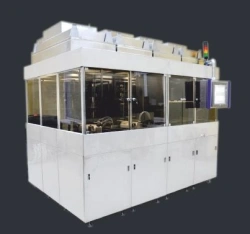

Coating unit NIKA-15101

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

- hardening coatings: AlTiN, AlCrN, AlSiTiN, AlSiCrN;

- multiphase coatings: -TiN/nc-AlN, nc-TiAlN/a-Si3N4, etc;

- heat-resistant and heat-resistant coatings.

- surface nitriding

Coating methods and technologies: PVD, CVD, HiPIMS, CAE, CMS, PECVD, PN/C, PARNS, IPVD based on vacuum arc vaporisation (ARC) or similar method.

The unit realises the use of combined methods of sputtering by selecting interchangeable technological devices.

Operating manual available on request.

Technical Specifications

| Assignment | Designed for high density coating, for end tools and cutting inserts with deposition rate not less than 1.9 microns/hour, for ion-plasma low-temperature nitriding of workpiece surface and application of various functional coatings |

|---|---|

| Dustproof | Got it |

| Type of construction | Stationary |

| Guaranteed lifetime of the plant | 12 months from the date of signing the commissioning certificate of the plant |

| Warranty shelf life of the system | 18 months from the date of delivery |

| Service life of the plant until decommissioning | 5 years |

| Resources and service life of components and purchased products | are determined in accordance with their operating documents |

| Climatic designs | GOST 15150-69; GOST 15543-70 at normal values of climatic factors of external environment - UHL for product placement category 4.2. |

| Execution | according to design documentation NIKA-15101 coating unit |

| Installed capacity | 121715 W |

| Maximum power consumption | No more than 100 kW |

| Power supply voltage | 380(10±15%) V |

| Power supply connection diagram | TN-C (three-phase four-wire, neutral protective and neutral working conductors are combined in one conductor) |

| Maximum current consumption by phase | 184,42 A |

| Ultimate vacuum | not more than - 0.0006 |

| Chamber pressure 30 minutes after the start of pumping | Not more than 0.005 |

| Air flow after pumping the chamber for 30 min, ncm3/min | Not more than 0.3 |

| Maximum working temperature for heating workpieces | 600 °C |

| Working gases | argon GOST 10157-2016, nitrogen GOST 9293-74, hydrogen GOST 3022-80, air |

| Number of gas supply channels | 5 pc |

| Pressure control range by gas flow | 0,1-0,5 |

| Working fluid (recommended) | Distilled water, 20% solution of ethyl alcohol in distilled water according to GOST 6709-72 |

| Working fluid volume, l | No more than 15 |

| Cooling water flow rate, m³/hour | max, 1.5 |

| Compressed air flow rate, m³/min | Not more than 0.02 |

| Weight of the unit (excluding the forevacuum unit, cryogenic pump compressor unit, water recycling system, | no more than 2300 kg |

| Overall dimensions of the unit on the transport base (length x width x height) | max. 2800 x 1230 x 2260 mm |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

Vacuum deposition unit UVN-74P-3M-1

View Details

Photolithography cluster line

View Details

Vacuum unit for reactive-ion layer etching with sluice loading PLASMA TM 7

View Details

VACUUM MAGNETRON SPUTTERING MACHINE WITH SLUICE LOADING MAGNA TM 22

View Details

SMALL-SIZE VACUUM UNIT FOR PLASMA CHEMICAL CLEANING, PHOTORESIST REMOVAL AND STERILISATION PLASMA TM 4

View Details

MAGNA TM 7 magnetron sputtering vacuum film spraying unit

View Details

Vacuum spraying unit UVN-71P-3M-1

View Details

Installation for deposition of thin films of metals, resistive alloys and dielectrics by magnetron ion-beam sputtering method.

View Details

Four-position vacuum plant with magnetron sputtering systems MAGNA TM 5.

View Details

Solder paste melting furnace

View Details

MAGNETRON SPUTTERING VACUUM COATING PLANT WITH SLUICE LOADING FROM CASSETTE TO CASSETTE MAGNA TM 29

View Details

VACUUM MAGNETRON SPUTTERING MACHINE WITH SLUICE LOADING MAGNA TM 22

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions