Available for Import

Available for Import

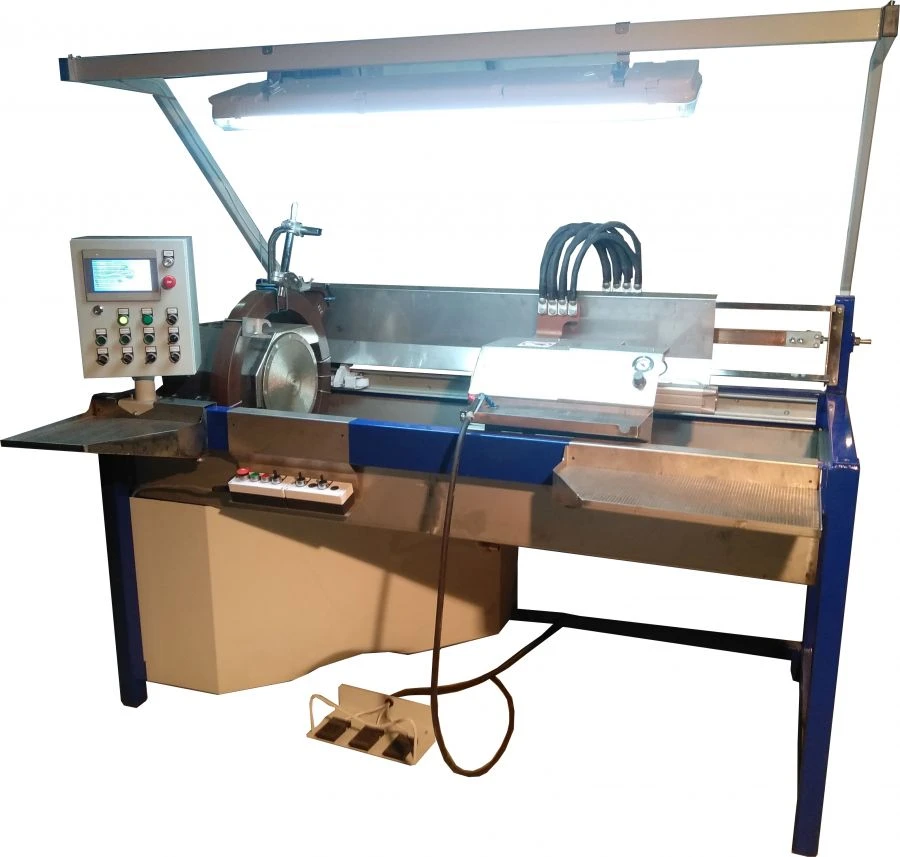

Magnetic powder flaw detector MAGNITEST-U 1000

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Magnitepowder flaw detector MAGNITEST-U 1000 provides detection of longitudinal and transverse defects with minimum dimensions (in accordance with GOST R 56512-2015): opening 0.0001 mm, depth 0.01 mm, length 0.5 mm, as well as larger ones.

In accordance with GOST 21105-87 sensitivity classes "A", "B", "C" are provided.

Advantages:

- automation of control operations;

- design of contact plates excluding "burns";

- input of currents up to 12 kA during part rotation;

- library of parameters of product control;

- simultaneous magnetisation and inspection of the clamped part;

- automatic maintenance of the circular magnetising current value;

- parameter setting and display on a touch screen with intuitive interface;

- smooth adjustment of the magnetising currents;

- magnetising current measurement system RSI;

- slurry splash protection system;

- white light or ultraviolet illumination;

- placement of a blackout system on the installation, if necessary.

In accordance with GOST 21105-87 sensitivity classes "A", "B", "C" are provided.

Advantages:

- automation of control operations;

- design of contact plates excluding "burns";

- input of currents up to 12 kA during part rotation;

- library of parameters of product control;

- simultaneous magnetisation and inspection of the clamped part;

- automatic maintenance of the circular magnetising current value;

- parameter setting and display on a touch screen with intuitive interface;

- smooth adjustment of the magnetising currents;

- magnetising current measurement system RSI;

- slurry splash protection system;

- white light or ultraviolet illumination;

- placement of a blackout system on the installation, if necessary.

Specifications

Type of product according to PP RF 616

Instruments and other instruments for measurement, control and testing

Maximum size of the controlled object, length

1000 mm

Maximum weight of the controlled object

100 kg

Type of magnetizing current

AC, DC

Maximum distance between contact plates

1000 mm

Amplitude of circular magnetizing current

100...12000 A

Current maintenance accuracy

10 %

Value of longitudinal magnetic field strength between headstocks separated by 500 mm, A/cm, not less than

100

Value of longitudinal magnetic field strength in the center of the contact plate, A/cm, not less than

500

Maximum value of longitudinal magnetic field strength in the center of the longitudinal magnetizing solenoid, A/cm

400

Illumination of the control object surface with white light, not less than

1000

Intensity from UV source on the carriage, µW/cm2

2000

Maximum size of the controlled object

400...700 mm

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Magnetic powder flaw detector MAGNITEST M-500

View Details

Demagnetising and demagnetising unit ErMag RMU 520x200

View Details

STEEL CANAT Wear Meter (flaw detector) INTROS MG450P

View Details

Wear Meter for Steel Knuckles (flaw detector) INTROS MG6-24

View Details

Numbered antimagnetic control seal "IMP SILMAG"

View Details

Magnetopowder flaw detector ErMag 1000

View Details

Magnetic powder flaw detector ErMag 1000 SLIM

View Details

Wear Meter for Steel Knuckles (flaw detector) INTROS MG 6-26

View Details

Bug for magnetopowder suspension ErMag

View Details

Defectoscopes for monitoring of steel ropes automated INTROS-AUTO

View Details

STEEL CANAT Wear Meter (flaw detector) INTROS MG24-64

View Details

Wear Meter for Steel Tubes (flaw detector) INTROS MG22-45

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions