Available for Import

Available for Import

Installation for pressure testing of hydraulic cylinder-heads of UG series

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Model range: UG1000, UG1200, UG1400, UG1500, UG1600.

The UG series hydraulic test rig is designed to test both the blocks themselves and cylinder heads. The principle of operation of the equipment is to test assemblies for tightness using compressed air in a water environment.

The temperature of water in the tank is brought to the required temperature by means of a tubular electric heater (TEN). The part under examination is fixed to the turntable by special clamps supplied in the set. Compressed air from the pneumatic system (standard compressor) is supplied to the part. Raising/lowering of the rotary table is carried out by a reliable Italian hydraulic station. By means of the electric drive of the rotary table rotation, the workpiece is rotated at any angle, which provides access to all hidden cavities. A convenient 4-position joystick located on the control panel is designed for all working operations. The pressure is monitored by a pressure gauge.

The UG series hydraulic test rig is designed to test both the blocks themselves and cylinder heads. The principle of operation of the equipment is to test assemblies for tightness using compressed air in a water environment.

The temperature of water in the tank is brought to the required temperature by means of a tubular electric heater (TEN). The part under examination is fixed to the turntable by special clamps supplied in the set. Compressed air from the pneumatic system (standard compressor) is supplied to the part. Raising/lowering of the rotary table is carried out by a reliable Italian hydraulic station. By means of the electric drive of the rotary table rotation, the workpiece is rotated at any angle, which provides access to all hidden cavities. A convenient 4-position joystick located on the control panel is designed for all working operations. The pressure is monitored by a pressure gauge.

Specifications

Absolute error tolerance limits of the probe head MPER, µm

3000

Limits of permissible absolute error of volumetric measurements MPEE, µm

3000

Number of simultaneously and coherently controlled coordinates

1 pc

Linear displacement sensor resolution (µm)

3000

X-axis travel range

0...200 mm

Y-axis travel range

0...300 mm

Z-axis travel range

10...500 mm

Permissible part weight

250...350 kg

Type of product according to PP RF 616

Instruments and other instruments for measurement, control and testing

Type of product according to PP RF 616

Instruments and other instruments for measurement, control and testing

Workpiece length

1000...1500 mm

Maximum part weight

250...350 kg

Total length of the machine

1650...2360 mm

Total width of the unit

1250...1700 mm

Total installation height

1600...1750 mm

Scope

0.53...1.8

Pressure

0.5 MPa

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Ship's trace-searching system STPS

View Details

Sputnik tool gauge

View Details

Hardware-software complex of weighing vehicles in motion, built with the use of fibre-optic

View Details

TOPAZ TM telecontrol modules DOUT

View Details

Brake power brake bench - STS-16U-SP-11

View Details

Universal telecom network analyser Berkut-MTI (-O) FIYAG.468169.001

View Details

Submersible telemetry systems "Elekton-TMS"

View Details

Receiving coils KP

View Details

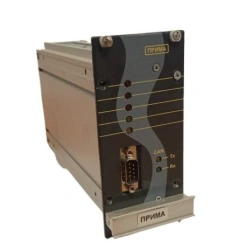

Converter-information module automated PRIMA

View Details

Heat meter "Pulsar"

View Details

TOPAZ MU process bus interface devices

View Details

Telemechanics modules TOPAZ TM MTU

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions