Available for Import

Available for Import

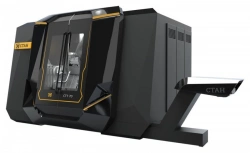

Turning centre lathe of CA1100C50F2 model

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The machine tool with an operational control system (OCS) is a new generation machine tool, corresponding to the modern trends of the world machine tool industry.

- The machine tools replace the traditional universal machine tools.

- Compared to universal machine tools, machines with operational control system provide higher productivity (1.5 - 2 times) and quality, and their maintenance does not require such a high qualification as when working on numerically controlled machines (CNC).

- The use of servo feed drives and ball screws instead of mechanical kinematic links increases the accuracy and reliability of the machine tool and reduces operating costs.

- Parts with complex geometry, including cones, spheres and threads, can be machined without the use of complex fixtures and changeovers.

- The machine can be equipped with a turret with automatic tool change instead of a manual toolholder.

- The machine tools replace the traditional universal machine tools.

- Compared to universal machine tools, machines with operational control system provide higher productivity (1.5 - 2 times) and quality, and their maintenance does not require such a high qualification as when working on numerically controlled machines (CNC).

- The use of servo feed drives and ball screws instead of mechanical kinematic links increases the accuracy and reliability of the machine tool and reduces operating costs.

- Parts with complex geometry, including cones, spheres and threads, can be machined without the use of complex fixtures and changeovers.

- The machine can be equipped with a turret with automatic tool change instead of a manual toolholder.

Specifications

Type of product according to PP RF 616

Turning and screw-cutting machines (universal, with CNC, CNC)

Machine weight, not more

15000 kg

Length

9183 mm

Width

2329 mm

Height

2200 mm

Width (without remote control/ with remote control)

3059 mm

Largest diameter of the workpiece to be mounted above the bed

1080 mm

Largest diameter of the workpiece to be machined above the slide

860 mm

Maximum mass of the part to be installed

8000 kg

X-axis travel (transverse movement of the slide)

625 mm

Z-axis travel (longitudinal movement of the slide)

4920 mm

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Horizontal CNC lathe model 160HT

View Details

CNC lathe-carousel machine model 1?516??3.??

View Details

Lathe with LSU CA500CF2

View Details

CNC lathe CA500C30F3

View Details

CNC lathe NT700C18F3

View Details

CNC LATHE NT700F3

View Details

CNC lathe CA983C10F3

View Details

CNC chuck centre lathe 16R30F3-3

View Details

Proton T type CNC horizontal lathe, model Proton T160

View Details

Proton T type horizontal CNC lathe Proton T250 (with any CNC system)

View Details

CNC Turning Centre Model 1728C-1

View Details

Turning machining centre with 500mm Sections Model 1715Y-2D

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions