Available for Import

Available for Import

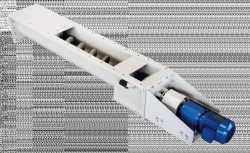

Screw conveyors type U21-BKV for food industry: U21-BKV-25-25

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

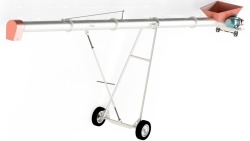

Screw conveyors are designed for horizontal or inclined (up to 20 degrees) movement of grain and products of its processing. They are used as part of technological lines of elevators, mills, groats plants, feed mills, FDS, MOB, oil plants.

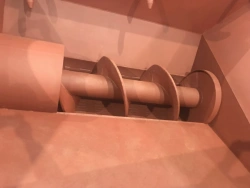

Screw conveyors consist of the following parts: a screw formed by a spiral surface welded to a tubular shaft; a chute or a cylindrical casing with discharge outlets; intermediate (suspended) and end bearings, one of which is thrust; drive.

The principle of operation of screw conveyors is based on the continuous movement of grain rotating auger, installed in a stationary chute. There is a distinction between slow-moving and fast-moving screw conveyors. In slow-moving horizontal and declined conveyors the product is kept from turning by the force of gravity and friction on the chute. Once in the working area of the auger, the product slides along the auger from the loading area to the unloading area in a spiral motion. The auger is driven at....

Screw conveyors consist of the following parts: a screw formed by a spiral surface welded to a tubular shaft; a chute or a cylindrical casing with discharge outlets; intermediate (suspended) and end bearings, one of which is thrust; drive.

The principle of operation of screw conveyors is based on the continuous movement of grain rotating auger, installed in a stationary chute. There is a distinction between slow-moving and fast-moving screw conveyors. In slow-moving horizontal and declined conveyors the product is kept from turning by the force of gravity and friction on the chute. Once in the working area of the auger, the product slides along the auger from the loading area to the unloading area in a spiral motion. The auger is driven at....

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Screw stripping mechanism type MSHZ

View Details

U21-BKV type screw conveyors for food industry: U21-BKV-20-20

View Details

Mechanised slag removal plant

View Details

Self feeders of screw type USSH, UKV

View Details

Screw conveyor (conveyor)

View Details

Screw slag remover 154.20.42.030 MCH

View Details

Screw feeder

View Details

Stationary screw conveyor of VHF type of VHF model VHF - 320

View Details

Screw conveyors of VKV type

View Details

Stripping screw type SR

View Details

Radial screw conveyor type ???

View Details

Stationary screw conveyor model UHT modification UHT - 500-2 (in a pipe)

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions