Available for Import

Available for Import

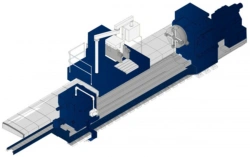

CNC lathe CA600F3

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The CA600F3 CNC lathe combines high-speed machining capabilities, high positioning accuracy and repeatability, and high torque.

-All of these features expand the machine's processing capabilities, allowing for greater flexibility in the way tasks are performed

-The rigid solid cast iron bed, artificially aged to relieve internal stresses, ensures long term stability of the machine's geometric accuracy.

-Wide prismatic and flat slideways, hardened to a depth of 1.5-2 mm to a hardness of 52HRC and ground, ensure high durability.

-Surfaces of travelling units (carriage, tailstock) are scaled and coated with special antifriction coating for travelling with minimum wear.

The machine has modifications CA600C10F3, CA600C15F3, CA600C20F3, CA600C30F3.

-All of these features expand the machine's processing capabilities, allowing for greater flexibility in the way tasks are performed

-The rigid solid cast iron bed, artificially aged to relieve internal stresses, ensures long term stability of the machine's geometric accuracy.

-Wide prismatic and flat slideways, hardened to a depth of 1.5-2 mm to a hardness of 52HRC and ground, ensure high durability.

-Surfaces of travelling units (carriage, tailstock) are scaled and coated with special antifriction coating for travelling with minimum wear.

The machine has modifications CA600C10F3, CA600C15F3, CA600C20F3, CA600C30F3.

Specifications

Type of product according to PP RF 616

Turning and screw-cutting machines (universal, with CNC, CNC)

Length

3297 mm

Width

1620 mm

Height

2170 mm

Machine weight, not more

2800 kg

Largest diameter of the workpiece to be mounted above the bed

560 mm

Largest diameter of the workpiece to be machined above the slide

320 mm

X-axis travel (transverse movement of the slide)

278 mm

Z-axis travel (longitudinal movement of the slide)

896 mm

Positioning accuracy

1 mm

Z-axis screw diameter

40 mm

Z-axis screw pitch

10 mm

Z-axis drive power

1 kW

X-axis screw diameter

32 mm

X-axis screw pitch

5 mm

X-axis drive power

1 kW

Maximum spindle speed

2800

Chuck diameter

315 mm

Diameter of the hole in the spindle for the bar

102 mm

Tool change time

45

Number of tool slots

8 pc

Diameter of tailstock quill

100 mm

Maximum coolant pump pressure

2

Coolant tank capacity

140 l

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Numerically controlled metal turning machine ST16A25/1000

View Details

Lathe with LSU CA500C30F2

View Details

Diamond turning machine A-500

View Details

Centre lathe 1525F1.400

View Details

CNC lathe CAT630C10F3

View Details

CNC lathe model CA1800F3

View Details

CNC lathe model RT817F3

View Details

CNC lathe model CA1400C70F4

View Details

CA500F2K lathe

View Details

Proton T type CNC horizontal lathe, model Proton T160

View Details

CNC lathe "MT-45" of UNIMATIC trade mark with IntNC PRO type CNC system (Ivanovo, Russia)

View Details

CNC lathes of "MT" series of "Unimatic" trade mark

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions