Available for Import

Available for Import

CNC lathe model CA1800F3

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Available Models

Description

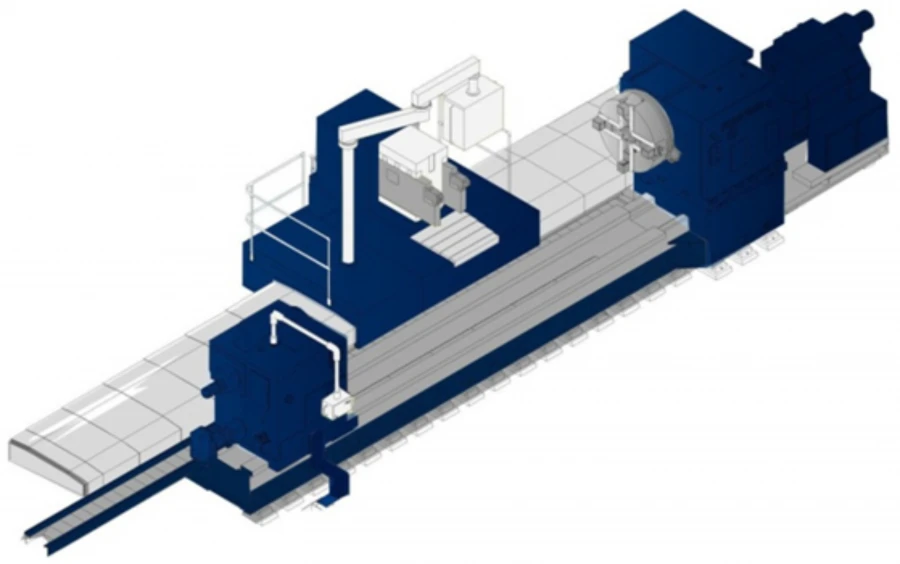

Toking machines CA1800F3 (with modifications CA1800C30F3, CA1800C50F3, CA1800C70F3, CA1800C80F3, CA1800C100F3, CA1800C120F3, CA1800C140F3, CA1800C160F3, ??1800?180?3, ??1800?200?3, ??1800?220?3, ??1800?240?3) with through slides provide optimal technology of machining of long parts. Due to the fact that the slides can bypass the lunettes, go behind the spindle headstock and tailstock, the workpiece is machined along the entire length without reinstallation.

The machine bed is made of solid cast iron sections, with 4 or 5 guideways: 2 or 3 rolling guides for slides, 2 sliding guides for tailstock and lunettes. The sections are fastened together with high-strength bolts and pins.

Spindle headstock. Range switching is automatic. Speed control within each range is stepless.

Caliper. Two slides move along the Z-axis on rolling guides. Slides are mounted on the slides, which move along the X axis.

The machine bed is made of solid cast iron sections, with 4 or 5 guideways: 2 or 3 rolling guides for slides, 2 sliding guides for tailstock and lunettes. The sections are fastened together with high-strength bolts and pins.

Spindle headstock. Range switching is automatic. Speed control within each range is stepless.

Caliper. Two slides move along the Z-axis on rolling guides. Slides are mounted on the slides, which move along the X axis.

Specifications

Type of product according to PP RF 616

Lathes

Length

31200 mm

Width

3500 mm

Height

3000 mm

Machine weight, not more

186800 kg

Accuracy class according to GOST 8-82

"?"

Largest diameter of rotation of the workpiece above the bed

1800 mm

Largest diameter of the workpiece above the slide

1200 mm

Maximum length of the workpiece to be machined in the centers

24000 mm

Maximum mass of the part to be fitted: - in chuck/centres

20000 kg

Spindle bore diameter

150 mm

Specific spindle end dimension according to DIN 55026

?20

Spindle speed limits

1-400 rpm

Speed control

stepless

Main drive power

110 kW

Maximum torque

32000 Nm

Support in X1, X2 axes

720 mm

Support in axes Z1, Z2

14700 mm

C-axis support

± 360 deg.

Working feed rate range in X, Z axes

1-5000 mm/min

Working feed rate range in the C-axis

0.05 - 2 rpm

Accelerated movements in X1, X2 axes

6000 mm/min

Accelerated movements in axes Z1, Z2

10000 mm/min

Accelerated movements in the C-axis

10

Number of turret tool positions on the left slide

4 pc

Largest cross-section of the turret toolholder on the left slide

40*40 mm

Type of turret tool attachment on the left slide

DIN 69881

Tool change time per turret position on the left slide

7.5

Tool change time to the furthest turret position on the left slide

15

Number of turret tool positions on the right slide

4 pc

Largest cross-section of the turret toolholder on the right-hand slide

40*40 mm

Type of turret tool attachment on the right-hand slide

DIN 69881

Tool change time per turret position on the right slide

7.5

Tool change time to the furthest turret position on the right slide

15

Moving the tailstock quill

300 mm

Diameter of tailstock quill

400 mm

Internal taper in the quill of the tailstock

Morse 6

Clamping force of the tailstock quill pin

5-70 kN

Type of tailstock quill drive

Hydraulic

Maximum longitudinal quill compensation for thermal expansion of the tailstock

3 mm

Speed of rapid movements of the tailstock

1500 mm/min

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Diamond turning machine A-500

View Details

MT-210 CNC Turning Centre

View Details

CNC lathe "MT-65" of UNIMATIC trade mark with IntNC PRO type CNC system (Ivanovo, Russia)

View Details

CNC Turning Centre Model 1740Y-2D-1

View Details

CNC lathe "MT-95" of UNIMATIC trade mark with IntNC PRO type CNC system (Ivanovo, Russia)

View Details

Proton T type CNC horizontal lathe, model Proton T800L

View Details

Two-axis universal CNC lathe CTX 510 V1 ecoline (Universal CNC lathe CTX 510 V1 ecoline)

View Details

CNC tilting lathe machining centre CAT630F4

View Details

CNC lathe of model 16?70F3-1

View Details

Special CNC wheel lathe model RT905F3

View Details

Horizontal CNC lathe with rolling guides CA500F4K

View Details

CNC lathe-carousel machine model 1?516??3.??

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions