Available for Import

Available for Import

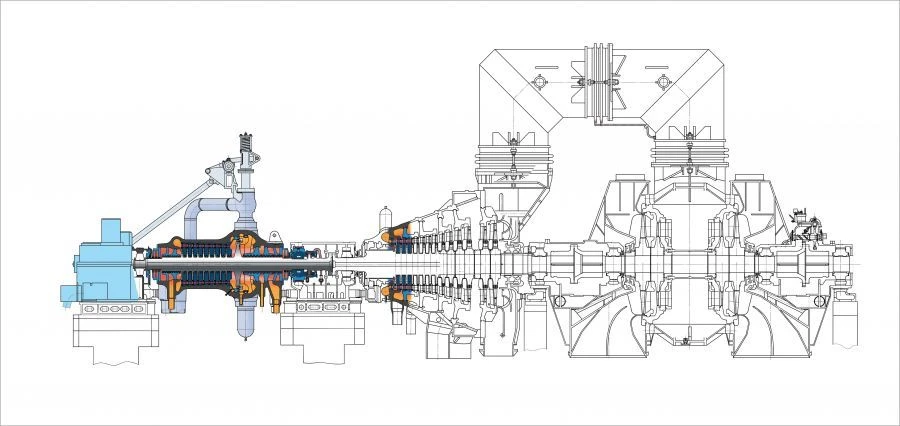

Assemblies and parts for modernisation of steam heating turbine T-100 with replacement of high pressure cylinder (HPCC) with inc

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The project of modernisation of the turbine T-100/120-130-2 provides for delivery of a new DDC with a single regulating stage (RS) and nine pressure stages, as well as a number of other parts and assemblies, including a modernised cam distributor with a reinforced frame, modernised regulating and stop valves, support bearing with modernised thrust pads of increased bearing capacity. Heating of the flange connection of the DDC is made through the flange skirts of the DDC horizontal connector. The VD rotor is made with a half coupling of the coupling coupling of the VD rotor and SD rotor.

Turbine modernisation provides:

- improvement of steam distribution operation;

- increase of turbine efficiency due to optimisation of the flow part.

Designation of the turbine after Modernisation: T-110/120-12,8 PR3-1.

Turbine modernisation provides:

- improvement of steam distribution operation;

- increase of turbine efficiency due to optimisation of the flow part.

Designation of the turbine after Modernisation: T-110/120-12,8 PR3-1.

Specifications

Minimum scope of modernization

modernisation of t-100 series turbine replace resource nodes and parts; operating at temperature more than 450°c. it allows to renew resource; and also to increase nominal; maximum power and heat load in condensing mode.

Average volume of modernization

in addition to replacement of high-pressure cylinder life assemblies and parts; additionally includes replacement of medium-pressure flow section; and by-pass tubes from high-pressure cylinder to medium-pressure cylinder.

Maximum scope of modernization

in addition to the medium variant, the low-pressure flow part is replaced; this allows to increase the reliability of the low-pressure part operation

Set

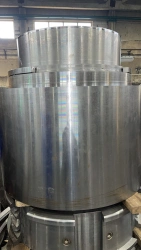

CVD

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

CND rear seal KE16.139.01.000

View Details

Special check valve KOS 200-1M4

View Details

Guide ring PS200.1513691

View Details

Set of items for technical modernisation of T-100/120-130-2 turbine

View Details

Set of subassemblies and parts of CND flowing part for steam turbine K-210-130 of power unit st.? 8 (stock No.1709) of Primorska

View Details

Water vapour turbine part: high pressure cylinder assembly, medium pressure cylinder assembly, including stop valve and control

View Details

K-200-130 turbine CND diaphragm collar

View Details

Coupling half with fasteners PS.100.201.06.000

View Details

Water vapour turbine part T-50: high pressure cylinder assembly including stop valve and control valves

View Details

Diaphragm 1 st. CND of turbine T-96/110-90

View Details

??????? ??.100.304.01.000

View Details

Special check valve KOS-400-1M2,5

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions