Available for Import

Available for Import

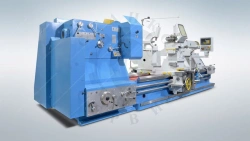

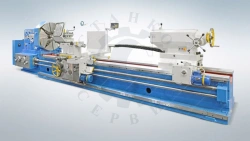

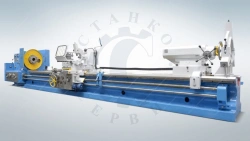

Universal pipe cutting machine CA983C (with modifications CA983C010, CA983C020, CA983C030)

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Easy to use pipe cutting machine designed for processing of long pipes and pipe joint parts with diameter up to 340 mm, used for oil and natural gas production and transportation.

It is also suitable for all types of turning operations, including cutting metric and inch threads, including tapered threads.

It is equipped with a hydraulic mechanism for automation of one threading pass (hydro-bounce) during thread cutting both in manual mode and in a cycle.

The machine has modifications CA983C010, CA983C020, CA983C030.

Technical Specifications

| Type of product according to PP RF 616 | Turning and screw-cutting machines (universal, with CNC, CNC) |

|---|---|

| Height | 1675 mm |

| Width | 2050 mm |

| Length | 3640 mm |

| Accelerated Z-axis travel (longitudinal movement) | 5300 mm/min |

| Tailstock quill taper | Morse 6 |

| Diameter of tailstock quill | 120 mm |

| Moving the tailstock quill | 240 mm |

| Turning mechanism | Manual |

| Cutter section | 32x32 mm |

| Number of tool positions | 4 pc |

| Spindle bore diameter | ?340 |

| Chuck type | Mechanized |

| Chuck diameter | ø720 (ø630)* mm |

| Main engine power | 15 kW |

| Speed control | Step, 12 steps |

| Maximum torque | 3000 nm |

| Spindle speed | 8 - 355 rpm |

| Pitch limit of threads to be cut, inch | 28-1 threads per inch |

| Pitch limit of the thread to be tapped, metric | 1-28 mm |

| Working range of longitudinal feed rates | 0,09 - 2,67 mm/rev |

| Working range of cross feeds | 0,042 - 1,179 mm/rpm |

| Accelerated movement in X axis (transverse movement) | 2200 mm/min |

| Z-axis travel (longitudinal movement) | 1000/2000/3000 mm |

| Travelling in X axis (transverse movement) | 500 mm |

| Maximum length of workpiece to be machined with tapered ruler | 500 mm |

| Largest diameter of the workpiece to be machined above the slide | 450 mm |

| Largest diameter of the workpiece to be mounted above the bed | 830 mm |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

Screw Centre Lathe 16K40-8

View Details

CA750C30F2K lathe with on-line control system

View Details

Turning and screw-cutting machine 16K40F1

View Details

KU-695 Lathe-drilling-milling machine

View Details

Transresonance balancing machine with horizontal axis of rotation VM-010

View Details

Turning and screw-cutting machine tool RT317F1-3

View Details

Universal bench drilling machine NS-16

View Details

Turning and screw-cutting machine tool RT817F1-5

View Details

Universal turning and screw-cutting machine of model 1M63N-1,5

View Details

Resonant balancing machine with horizontal axis of rotation BM-1000

View Details

Turning and screw-cutting machine of model 1M63H

View Details

Screw-cutting lathe 1N65-12

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions