Available for Import

Available for Import

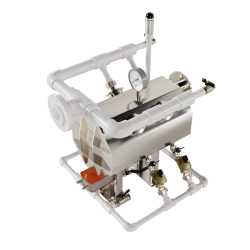

System MO-1000

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

The equipment is mounted on a frame made of anodised aluminium machine profile equipped with vibration-isolating wheels. Pipelines of the water treatment plant are made of polypropylene pipes, electrical communications are laid in polyamide corrugated pipe.

Water treatment technology. Source water is supplied from the water supply system to the injection reactor of the plant. In the reactor oxidation by injected air of hydrogen sulphide, iron and manganese compounds contained in water on fluidised catalytic filling takes place. The suspended solids formed during oxidation are collected in the fixed bed of the catalytic backfill.

The water from the reactor flows to the multi-patron filter, where the remaining fine suspended solids, wear products of the catalytic backfill and dissolved organic substances are captured on filter-sorption cartridges.

The water is supplied with a dose of antiscalant and is pumped by a high-pressure pump into the RO membrane housing, where it is separated by the membrane into a desalinated permeate and a salt-enriched concentrate. The concentrate is discharged into the sewer. The treated water is fed into a storage tank.

From the storage tank the water is supplied to the consumer by a stainless steel distribution pump.

Each time the storage tank is filled, the system stops operation and automatically backflushes the catalytic backfill in the reactor with water from the storage tank.

The system automatically stops operation when the pressure in the inlet water pipe drops below 0.2 MPa and informs the user about this emergency situation by switching on the red coloured indicator on the control panel.

The system informs the user about the need to replace filter-sorption cartridges by switching on the yellow coloured indicator on the control panel.

The system is equipped with a device for automatic water drainage from the multipatron filter housing to prevent untreated water from entering the RO membrane when replacing the filter-sorption cartridges.

The system is equipped with a unit for automatic withdrawal of the RO membrane after start-up to the operating mode according to the salt content in the permeate.

The unit provides water quality at the outlet in accordance with GOST 9.314-90 "Desalinated water" for the first category of water at source water corresponding to SanPiN 2.1.4.1074-01 "Drinking water. Hygienic requirements for water quality of centralised drinking water supply systems. Quality control".

When functioning, the system consumes filter-sorption cartridges, antiscalant and electricity. Directly for water treatment the system consumes up to 2.5 kWh per 1 m3 of treated water.

The drainage water of the system is non-toxic and its discharge into the sewerage network is allowed without additional treatment.

The system is fully automated and does not require user control.

Technical Specifications

| Length | 1000 mm |

|---|---|

| Width | 800 mm |

| Width | 800 mm |

| Height | 1800 mm |

| Average treated water capacity | 1 |

| System dry mass | 260 kg |

| Storage capacity | 2 |

| Peak water flow rate from the storage tank | 4 |

| Installed electrical capacity of the system | 4 kW |

| Drainage water flow rate | 0.8 |

| Pressure in the source water path at the system inlet | 0.2...0.6 MPa |

| Ambient temperature during storage and operation | 5...40 °C |

| Life before overhaul | 8000 |

| Assigned resource | 50000 |

| Power supply (380 V) | SBVVBG |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

AGMA-KOS series sewage treatment plants

View Details

BARRY010X series waste water shredder

View Details

Natural water treatment station (surface and underground sources) for water supply systems of "AGMA-VOS" series

View Details

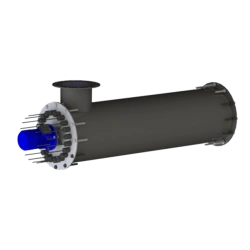

Ultraviolet disinfector VÖKKER UDC-Z-100

View Details

Automated installation for fine mechanical water purification from suspended substances UMV - 4

View Details

Combined sand and oil separator LOS KPN

View Details

Mechanical cleaning grids

View Details

System MO-50000

View Details

Combined mechanical wastewater treatment plant

View Details

PL series belt sieve filter press

View Details

Mesh Muffled LATUNE FILTERS for nominal pressure not exceeding PN 2,5 MPa (25 kgf/cm²), nominal bore (nominal di

View Details

Installation of MF-140

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions