Available for Import

Available for Import

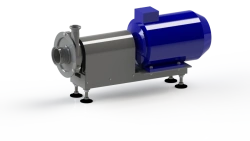

Oil formers of MOE model

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The butter maker is designed for production of all existing types of butter from high-fat cream by their transformation method.

Working principle

High-fat cream with the temperature of 60...70C is fed first into the lower cylinder of the butter maker, then successively moved through the middle one to the upper one. In each cylinder the cream is picked up by radial perforated blades during rotation of the displacing drum, mixed and thrown to the periphery. During the movement high-fat cream is cooled by the coolant coming into the jacket, scraped from the heat-exchange surface of the cylinder by knives and intensively mixed, passing under the knives through the grooves and holes of textural helical combs. The cooled product is further mechanically processed by passing through the area of rotating perforated blades and holes of two parallel discs located at the outlet of the cylinder. During the passage through the three cylinders of the apparatus, the high-fat cream is converted into a ...

Working principle

High-fat cream with the temperature of 60...70C is fed first into the lower cylinder of the butter maker, then successively moved through the middle one to the upper one. In each cylinder the cream is picked up by radial perforated blades during rotation of the displacing drum, mixed and thrown to the periphery. During the movement high-fat cream is cooled by the coolant coming into the jacket, scraped from the heat-exchange surface of the cylinder by knives and intensively mixed, passing under the knives through the grooves and holes of textural helical combs. The cooled product is further mechanically processed by passing through the area of rotating perforated blades and holes of two parallel discs located at the outlet of the cylinder. During the passage through the three cylinders of the apparatus, the high-fat cream is converted into a ...

Specifications

Length

1870 mm

Width

825 mm

Height

1775 mm

Performance

550...800 kg

Coolant flow rate

Built-in memory card slot, support microSD/SDHC/SDXC card (up to 256GB); manual recording/alarm recording

Refrigerant pressure

0.3 MPa

Installed motor power

7.4 kW

Weight

950 kg

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

???????????????? ?4-4000

View Details

Dispersing units, models P8-ORD, P8-ODS, dry milk recovery units and solvents for dry components, model P

View Details

???????????????? ?4-3000

View Details

BACTOFUGE ROTOR-OBTZP-3

View Details

Melter stirrer DVAK M-200S for cheese masses of mozzarella, suluguni type

View Details

VDP-600 Long Pasteurisation Bath

View Details

ROTOR-OBZP-10 BACTOFUGE

View Details

Milk coolers M1-200

View Details

Tanks and apparatus for storing and processing milk and other food liquids, type OAB

View Details

???????????????? ?2-2500

View Details

Centralised washing stations model P8-OCM

View Details

Cheese preparation tub CB-500

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions