Available for Import

Available for Import

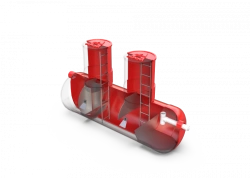

MO-120 machine

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Water treatment unit MO-120 (hereinafter referred to as the unit) is designed to purify water from open water bodies, wells and boreholes from suspended solids, colloids, disinfection from bacteria and viruses, removal of iron compounds, manganese, copper, sulfur, phosphorus, organic substances (including petroleum products), purification from dissolved salts, including hardness salts. The unit can be used to supply water to individual houses with simultaneous residence of up to 12 people at a consumption rate of 250 litres/person per day. If water is consumed only for drinking and cooking purposes, the unit can be used to supply water to up to 600 people.

The equipment of the unit is mounted on a frame made of anodised aluminium machine profile equipped with vibration-isolating wheels. The pipelines of the plant are made of polypropylene pipes, electrical communications are laid in polyamide corrugated pipe, high-pressure pump is mounted on vibration supports. Discharge of concentrate and reactor wash water into the sewerage system is performed through a jet breaker to exclude water ingress from the sewerage system into the unit. Water purification technology: The initial water enters the pre-filter inlet, where it is purified from mechanical impurities and dissolved organic substances (optional, depending on the type of cartridges used) and enters the multiphase injection reactor. In the reactor, water passing through the ejector is mixed with atmospheric air. The jet of water-air emulsion coming out of the ejector nozzle fluidises the catalytic backfill layer located above the nozzle. In fluidised layer intensive oxidation of dissolved impurities in water (iron, manganese, hydrogen sulphide, ammonia) takes place. Suspended solids formed during oxidation are captured by a fixed layer of catalytic backfill and removed by automatic backwashing of the reactor. The treated water from the reactor enters the post-filter, where suspended solids not caught in the catalytic bed, wear products of the bed, and dissolved organic matter adsorbed (optional, depending on the type of cartridges used) are removed. The treated water is then fed to the inlet of a high-pressure pump and pressurised into the nanofiltration membrane housings, where it is separated by the membranes into a desalinated permeate and a salt-enriched concentrate. The concentrate is discharged into the sewage system, and the concentrate discharge line also receives wash water from the reactor. The purified water is supplied with a preserving dose of sodium hypochlorite (optional, depending on the equipment of the plant) and enters the outlet pipeline.

The equipment of the unit is mounted on a frame made of anodised aluminium machine profile equipped with vibration-isolating wheels. The pipelines of the plant are made of polypropylene pipes, electrical communications are laid in polyamide corrugated pipe, high-pressure pump is mounted on vibration supports. Discharge of concentrate and reactor wash water into the sewerage system is performed through a jet breaker to exclude water ingress from the sewerage system into the unit. Water purification technology: The initial water enters the pre-filter inlet, where it is purified from mechanical impurities and dissolved organic substances (optional, depending on the type of cartridges used) and enters the multiphase injection reactor. In the reactor, water passing through the ejector is mixed with atmospheric air. The jet of water-air emulsion coming out of the ejector nozzle fluidises the catalytic backfill layer located above the nozzle. In fluidised layer intensive oxidation of dissolved impurities in water (iron, manganese, hydrogen sulphide, ammonia) takes place. Suspended solids formed during oxidation are captured by a fixed layer of catalytic backfill and removed by automatic backwashing of the reactor. The treated water from the reactor enters the post-filter, where suspended solids not caught in the catalytic bed, wear products of the bed, and dissolved organic matter adsorbed (optional, depending on the type of cartridges used) are removed. The treated water is then fed to the inlet of a high-pressure pump and pressurised into the nanofiltration membrane housings, where it is separated by the membranes into a desalinated permeate and a salt-enriched concentrate. The concentrate is discharged into the sewage system, and the concentrate discharge line also receives wash water from the reactor. The purified water is supplied with a preserving dose of sodium hypochlorite (optional, depending on the equipment of the plant) and enters the outlet pipeline.

Specifications

Length

900 mm

Width

300 mm

Height

850 mm

System dry mass

48 kg

Installed electrical capacity of the system

Flat grinder, Specialised grinder kW

Drainage water pressure at the system outlet

0.15...0.6 MPa

Ambient temperature during storage and operation

5...40 °C

Life before overhaul

4500

Assigned resource

1200

Average treated water capacity (liters)

Not less than: 120 l/h

Power supply (220 V)

SBVVBG

Average drainage water flow rate, l/h

not more than: 60 l/h

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Mechanised stepped sewer grating

View Details

Apparatus for deep water purification

View Details

Combined sand and oil separator LOS KPN

View Details

Combined sand and oil separator ICP-KPN

View Details

Bar grating with back rake RP

View Details

Drinking water preparation station SPPV-2

View Details

Mechanised rake sewer grating

View Details

Vökker FR-4R-P1-TR shield gate DN900

View Details

Shield gate Vökker FR-4N-P2-NK 1200 x 1200

View Details

Polymer aerator series APKV

View Details

Water treatment plants. PlanaVP water treatment plants for water treatment and drinking water purification.

View Details

Water treatment system "RLT - Crystal Ice".

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions