Available for Import

Available for Import

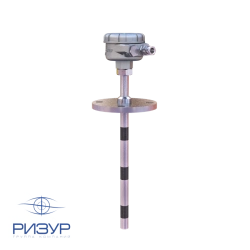

Magnetostrictive level gauge PMP-201E

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The converter is designed to measure parameters of liquid media,

including explosive ones, at accounting, calculation and technological operations.

The converter provides:

- liquid level measurement;

- measurement of interface level of two-phase liquid (when equipped with a float of interface); measurement of liquid level.

interface float);

- temperature measurement (multi-point, up to 8 points);

- liquid density measurement (on the liquid surface, when equipped with a

density measurement (on the liquid surface, when equipped with a density float);

- calculation of liquid density corresponding to the measured temperature,

according to the given initial data of density, temperature and coefficient of volumetric expansion of the liquid; calculation of liquid density corresponding to the measured temperature.

liquid expansion coefficient;

- calculation of the density of liquefied hydrocarbon gases (hereinafter referred to as - LHG) corresponding to the measured temperature

LPG) density corresponding to the measured temperature, according to the given component composition

composition;

- calculation of liquid volume according to the specified calibration table;

- calculation of the liquid volume for tanks with simple geometrical shapes

shapes;

- calculation of relative tank filling;

- calculation of liquid mass;

- Calculation of the mass of liquid and gas phase of LPG according to the given component composition

composition;

- issuing of control signals when the parameters of liquid media reach the set threshold values and/or in case of malfunction.

specified threshold values and/or in case of malfunction.

including explosive ones, at accounting, calculation and technological operations.

The converter provides:

- liquid level measurement;

- measurement of interface level of two-phase liquid (when equipped with a float of interface); measurement of liquid level.

interface float);

- temperature measurement (multi-point, up to 8 points);

- liquid density measurement (on the liquid surface, when equipped with a

density measurement (on the liquid surface, when equipped with a density float);

- calculation of liquid density corresponding to the measured temperature,

according to the given initial data of density, temperature and coefficient of volumetric expansion of the liquid; calculation of liquid density corresponding to the measured temperature.

liquid expansion coefficient;

- calculation of the density of liquefied hydrocarbon gases (hereinafter referred to as - LHG) corresponding to the measured temperature

LPG) density corresponding to the measured temperature, according to the given component composition

composition;

- calculation of liquid volume according to the specified calibration table;

- calculation of the liquid volume for tanks with simple geometrical shapes

shapes;

- calculation of relative tank filling;

- calculation of liquid mass;

- Calculation of the mass of liquid and gas phase of LPG according to the given component composition

composition;

- issuing of control signals when the parameters of liquid media reach the set threshold values and/or in case of malfunction.

specified threshold values and/or in case of malfunction.

Specifications

Supply voltage, V

4 to 15 (SENS)

Output type

SENS, RS-485 Modbus RTU

Explosion protection marking

Ga/Gb Ex db IIB T3

Degree of protection according to GOST 14254

IP66

Power consumption, mW, not more

100 (SENS)

400 (RS-485)

Assigned service life

15 a

Limits of permissible absolute error of temperature measurements, °C

±0.5 (range -40 to +60 °C)

Temperature of operation, storage, transportation

-50...60 °C

Temperature of the controlled medium

-50...60 °C

Permissible absolute error of density measurements, kg/m³

1 (for petroleum products)

Relative error limits of oil products and liquefied hydrocarbon gases mass measurement, %

±0.65 (range 0 to 120 t)

Permissible basic error of level measurements

-1...1 mm

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Level sensor LLT-MS

View Details

SUR signallers

View Details

RDS101 interface detectors

View Details

Bypass level indicators with sight glass RIZUR-NBK-GLASS-C series

View Details

Level gauge non-contact radar series RIZUR-2030

View Details

Magnetic float converter PMP-099

View Details

Top mounted float level transmitter UPB 1016

View Details

Multichannel level transmitters DUU10

View Details

RIZUR-300-MB series conductometric monoblock level switch

View Details

Reed level sensors PMP-115 with W5DNZ output

View Details

Ultrasonic level switches Ultratek

View Details

"Level relay "VARGUN" (set)".

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions