Available for Import

Available for Import

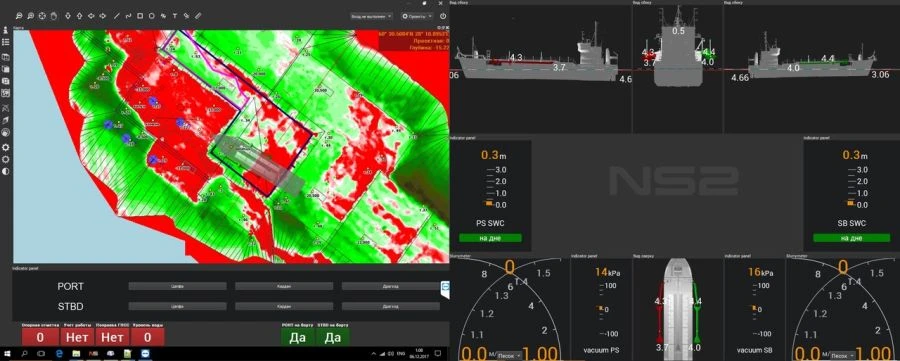

Hardware-software complex for automation, positioning, accounting of dredger productivity and control of dredger's performance u

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The software and hardware complex "Nonius" significantly increases the efficiency of dredging and mining operations. The complex serves for positioning and monitoring of dredgers and helps to find the optimal mode of operation of the vessel: - to reduce the number of downtimes; - to reduce the volume of abandoned work, work beyond the limits of scooping and beyond the design mark; - to keep an operational record of dredger output; - to reduce unnecessary costs, including fuel and maintenance. The dredge operator (bagger) can see the position of the dredge in relation to the depth map, the position of the dredge in relation to the bottom topography, the design depth and the design limits. In addition, the operator can always determine which areas have been worked on and which have not yet been worked on. Nonius will be useful for dredging and mining companies, as well as for mining and processing plants and large production facilities with tailings ponds. The complex can be installed on all types of dredgers.

Specifications

Absolute error of tilt angle measurement, degrees

+/- 0,35

Absolute error of roll/differential angle measurement, degree

+/- 0,05

Measured depth range of precipitation sensor

0...6 m

GNSS system

GPS/GLONASS

Positioning system error, sigma

1

Sensor protection class for determining the position of a soil sampling device 492238:Sensor protection class for determining th

IP68

Protection class of sensors for precipitation detection

IP68

Protection class of sensors for pulp velocity determination

IP67

Protection class for sensors for pulp density determination

IP66

Protection class of sensor data processing unit and satellite equipment

IP54

Humidity of the utilisation environment

100 %

Power consumption in 220 V circuit, not more than W (A)

100 (0,46)

Type of product according to PP RF 616

Other tools and instruments for measurement, inspection and testing

Positioning system error without additional corrections 492248:Positioning system error without additional corrections

3.5 m

Absolute error of pulp velocity sensor

0.1

Positioning system error in the coverage area of correction systems (SBAS, DGPS, DGLONASS)

1.5 m

Absolute error of precipitation measurement, m

+/- 0,01

Storage temperature of the tablet computer

5...60 °C

Angle of roll/differential measurement

-15...15

Storage temperature of information processing unit, external sensors, GNSS compass

-40...70 °C

Absolute error of pulp density sensor

SBVVBG

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Water leakage sensor RS-3225

View Details

Ohmmeter OA 3201

View Details

Azimuth DT

View Details

Seeding control system

View Details

8SC485 digital input expansion module

View Details

Brake power brake bench LTK-M3500

View Details

SNS probe st

View Details

Product E1846-01

View Details

Hardness tester ITB-3000-I-AS (RUS)

View Details

Reference radiator extended black body "Atlas"

View Details

TKAM-Air wireless tilt sensor

View Details

Spot quartz pressure and temperature sensor

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions