Available for Import

Available for Import

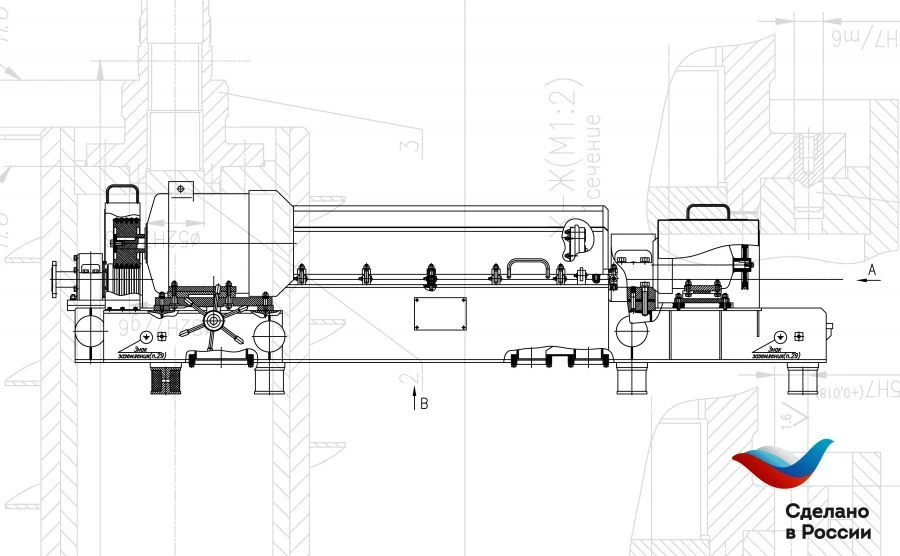

Decanter D-350

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Decanters of D type are horizontal continuous precipitators with screw discharge of sludge for processing of two-phase suspensions with stainless steel rotor.

They are used for processing of post-alcoholic barda and beer pellets, are part of the technological line for processing of animal waste, pig breeding, working in a flow mode, as well as part of technological lines for obtaining fish feed meal and technical fat.

The main unit of the decanter is the rotor of cylindrical shape, located horizontally. Rotor rotation is carried out from the motor by means of belt transmission.

Inside the rotor there is a screw coaxially located for transporting the precipitate of solid phase to the discharge windows of the rotor.

The screw is driven by the rotor via a gearbox. The auger rotates in the same direction as the rotor, but at a slower speed. The difference in speed between the screw and the rotor is necessary to force the sludge along the inner surface of the rotor.....

They are used for processing of post-alcoholic barda and beer pellets, are part of the technological line for processing of animal waste, pig breeding, working in a flow mode, as well as part of technological lines for obtaining fish feed meal and technical fat.

The main unit of the decanter is the rotor of cylindrical shape, located horizontally. Rotor rotation is carried out from the motor by means of belt transmission.

Inside the rotor there is a screw coaxially located for transporting the precipitate of solid phase to the discharge windows of the rotor.

The screw is driven by the rotor via a gearbox. The auger rotates in the same direction as the rotor, but at a slower speed. The difference in speed between the screw and the rotor is necessary to force the sludge along the inner surface of the rotor.....

Specifications

Weight

1800 kg

Main construction material

stainless steel

Temperature of the processed product

Flat grinder, Specialised grinder °C

Main drive power

5 kW

Working frequency of rotor rotation

3000

Electricity consumption per 1 cubic metre of slurry treated

5 kW

Humidity of discharged sludge

72 %

Dividing factor, largest

2683

Capacity for discharged sludge

3

Slurry capacity at 95% humidity, nominal

5...15

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Linear vibrating screen LSM-01

View Details

731K-10 horizontal screw sedimentation centrifuge

View Details

Fluid cleaning bench ???-933?1

View Details

Laboratory centrifuge for dairy industry CJ 1-65

View Details

44x132 sedimentation-filtering centrifuge

View Details

Centrifuge CLM1-12

View Details

Grease trap made of composite material according to "NTT" technology

View Details

Fluid cleaning bench SOG-913KTM

View Details

Fluid cleaning bench SOG-932KT1

View Details

Fluid cleaning bench ???-933?1

View Details

DLSM-01 sieve and hydrocyclone plant

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions