Available for Import

Available for Import

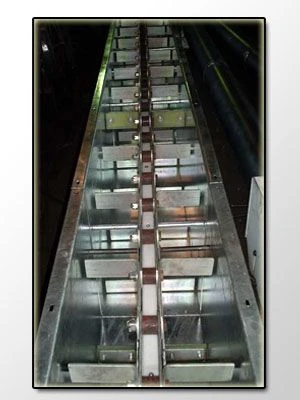

Conveyor (conveyor) chain scraper model SCC modification SCC-175

Bulk pricing available

FOB, CIF & EXW terms available

Available Models

Description

Conveyor chain (conveyor scraper chain) TCC for mechanical movement of bulk products in stationary conditions horizontally and at an angle of up to 60 degrees. The conveyor is a stationary conveying device of continuous action with a working traction organ - chain with scrapers. The main units of the conveyor are: drive head; drive; boxes of the inclined section; transitional elbow; boxes of the horizontal section; tension head; inside the boxes there is a chain with scrapers; drive clutch is closed with a casing; between the flanges of boxes there are sealing gaskets; boxes are connected with each other with bolts and nuts, on the end wall of the drive head there is an overflow sensor; on the side wall there is a chain break sensor.

In the body of the drive head there is a drive sprocket fixed on the shaft. In the lower part of the head housing there is a discharge opening of the conveyor. The drive is mounted on a separate frame and consists of an electric motor and a gearbox connected by an elastic coupling.

Transition elbow consists of two boxes connected by an axis on which the roller rotates. The inclined box can be rotated on the axis, which provides a change in the angle of inclination of the conveyor in the range from 15 ° to 60 °. The roller is used to bend the conveyor chain.

The principle of operation of the conveyor is as follows. When the electric motor is switched on, the leading sprocket drives the chain with scrapers, which moves the product along the bottom of the box towards the discharge opening of the drive head. The conveyor is loaded through holes in the box lids cut to fit.

To regulate the product feed and prevent the conveyor from slumping, gate valves should be installed on the loading holes. The conveyor should be installed in an enclosed room or under a canopy. Power source of the drive - AC electrical network of 50 Hz frequency, voltage 380 V.

Specifications

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Scraper Conveyor KSN-B-400 for Bulk Material Handling

View Details

Scraper Conveyor Type R1-KSP-320 for Grain Transport

View Details

Scraper Conveyors for Grain Transport - KS, KSP Models

View Details

Horizontal Scraper Conveyor KSV-350 for Grain Transport

View Details

KS Type Scraper Conveyors for Efficient Material Handling

View Details

Chain Scraper Conveyors for Bulk Material Transport KTs Series

View Details

Chain Scraper Conveyor for Grain Transportation KС-1000

View Details

Scraper Conveyor KTs-C250-25.5 (50 t/h) 25.5 m

View Details

Scraper Conveyor KTs-C400-14 (175 t/h) 14 m

View Details

Chain Scraper Conveyor Model TSC Modification TSC-250-U

View Details

Scraper Conveyor KSV for Horizontal Grain Transport

View Details

Chain Scraper Conveyor KSC Model KSC-175-01

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions