Available for Import

Available for Import

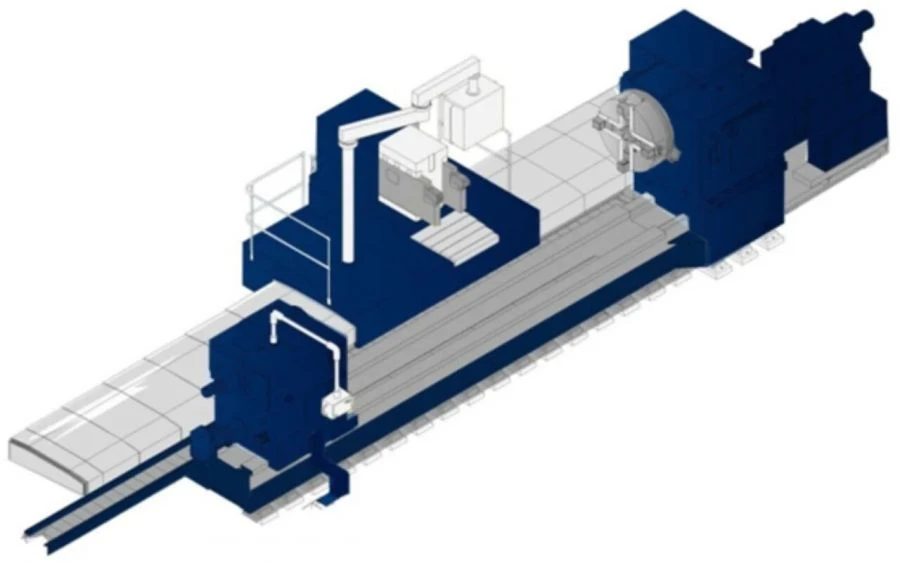

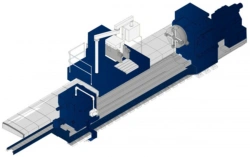

CNC lathe model ??1800?80F4

Bulk pricing available

FOB, CIF & EXW terms available

Description

The lathe with feed-through slides provides optimum technology for machining long workpieces. Due to the fact that the slides are able to bypass the lunettes, go behind the spindle headstock and tailstock, the workpiece is machined along its entire length without re-setting. The machine bed is made of solid cast iron sections, with 4 or 5 guideways: 2 or 3 rolling guides for slides, 2 sliding guides for tailstock and lunettes.

The sections are fastened together with high-strength bolts and pins. Spindle headstock with "C" axis. Range switching is automatic.

Speed control within each range is stepless. Caliper. Two slides move along the Z-axis on rolling guides.

The slides are fitted with sliders that move in the X axis. The right-hand caliper has an integral Y-axis on rolling guides.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

CNC Lathe Machine with Control System SA600C20F2

View Details

CNC Lathe Machine Model 16P70F3 for Precision Machining

View Details

Horizontal CNC Lathe Machine Proton T500K

View Details

SA983F2 CNC Lathe Machine with Advanced Control System

View Details

CNC Lathe Machine RT817F3 for Precision Machining

View Details

CNC Lathe Machine RT755F3 for Precision Turning

View Details

CNC Lathe Machine SA1800F3 for Precision Metalworking

View Details

High-Speed CNC Lathe Machine SA600F3

View Details

Horizontal CNC Lathe Machine Proton T320

View Details

CNC Turning Center for Comprehensive Processing MT-52

View Details

CNC Lathe Machine 16K20NK for Precision Metal Processing

View Details

CNC Lathe Machine SA800C40F3 for Precision Turning

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions