Available for Import

Available for Import

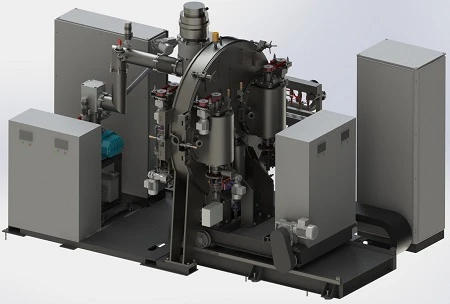

Automated Ion-Plasma Coating System MAP-5 for Turbine and Compressor Blades

Manufacturer:

National Research Center "Kurchatov Institute" - VIAM

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

The unit is designed for application of heat-resistant, corrosion-resistant, erosion-resistant, wear-resistant coatings on turbine blades and compressor blades of GTE, hard coatings from metal compositions on cutting tools and parts of GTE, and also allows to carry out ion etching and ion saturation of the treated surface with metal ions

Specifications

Number of parts with dimensions 80 × 180 mm to be machined simultaneously

10 pcs

Number of workpieces with dimensions 80 × 100 mm to be machined simultaneously

20 pcs

Number of simultaneously machined workpieces with dimensions

30 pcs

Speed of coating condensation on the substrate (at arc current 750 A), not more than, µm/minute

0.35

Pressure in the chamber during coating: metallic

0.0266...0.00665

Pressure in the chamber during coating: cermet coating

0.266...0.0665

Pumping duration up to working pressure of 0.0266 Pa, not more than

SBVVBG

Cooling water flow rate

20

Installed capacity

270 kW

Overall dimensions of the installation (dxhxv), not more than

4300 x 3100 x 3000 mm

Maximum dimensions of the spraying area on the workpiece, not more, (diameter × height)

80 x 380 mm

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Oil Quenching Tank for Hardening Parts BZM

View Details

Adhesive Additives Dosing Line Bastion LDA-1

View Details

IRS Technical Complexes for Material Processing with Temperature Change

View Details

High-Performance Vacuum Coating System Kurchatov

View Details

Portable Gas-Oxygen Pipe Cutting Devices GAKS-P

View Details

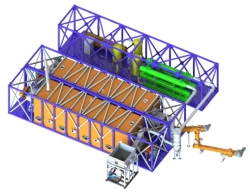

Automated Friction Stir Welding Complex for Aluminum Fabrication

View Details

Electric Tempering Bath Model VShZ for Cooling Applications

View Details

Thermal Destruction Units, Model UTD

View Details

Autoclave for Vulcanization AVTM 1000-1500-12.5-12X18N10T

View Details

Biological Waste Processing Installation UPO-6P for Animal Byproducts

View Details

Friction Welding Machine PST-150 for Drill Pipe Production

View Details

Autoclave for PCM Molding AT 3400-6500-12-EV black 441.340.00.00.000

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions