Available for Import

Available for Import

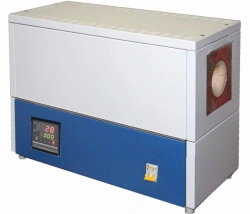

Thermovacuum unit

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Product application area:

-Temperature-vacuum drying of test objects within 24 hours at temperature up to 400 ° C and pressure not more than 1*10^-6 mm. Hg. according to OST 92-0019-78 after strength tests with distilled water or after washing with ethyl alcohol.

-Control of tightness of test objects at ambient temperature and pressure not more than 1*10^-6 mm Hg. by the method of "vacuumisation" in a vacuum chamber by comparison with a control leak.

The value of the ultimate residual pressure created in the vacuum chamber (without the test object) - not more than 5×10-7 mmHg.

The installation shall include the following units and assemblies:

- vacuum chamber with sliding frames;

- system of vacuum pumping of the chamber and test object;

- system of heating and temperature maintenance in the vacuum chamber and on the surface of the test object;

- helium leak detector;

- a set of helium control leaks;

- automated system for controlling the operating modes of the installation;

- in...

-Temperature-vacuum drying of test objects within 24 hours at temperature up to 400 ° C and pressure not more than 1*10^-6 mm. Hg. according to OST 92-0019-78 after strength tests with distilled water or after washing with ethyl alcohol.

-Control of tightness of test objects at ambient temperature and pressure not more than 1*10^-6 mm Hg. by the method of "vacuumisation" in a vacuum chamber by comparison with a control leak.

The value of the ultimate residual pressure created in the vacuum chamber (without the test object) - not more than 5×10-7 mmHg.

The installation shall include the following units and assemblies:

- vacuum chamber with sliding frames;

- system of vacuum pumping of the chamber and test object;

- system of heating and temperature maintenance in the vacuum chamber and on the surface of the test object;

- helium leak detector;

- a set of helium control leaks;

- automated system for controlling the operating modes of the installation;

- in...

Specifications

Heating temperature, max

400 °C

Pumping pressure, min

10...6

Heating channels, max

9 pc

Weight of objects, max

5000 kg

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Muffle furnace LF-9/13-V2

View Details

Bath oven SVG

View Details

Bathtub cooker SVSH

View Details

Vacuum post for electrovacuum treatment EVO-15/6-350

View Details

Bath oven SVM

View Details

High-temperature brazing furnace type VP-1325-16

View Details

Bath oven SVM

View Details

Muffle furnace LF-9/11-G1

View Details

Tube furnace LF-50/500-1200

View Details

Muffle furnace LF-7/11-V1

View Details

Muffle furnace LF-2/13-G2

View Details

LF-25/350-VS1 drying cabinet

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions