Available for Import

Available for Import

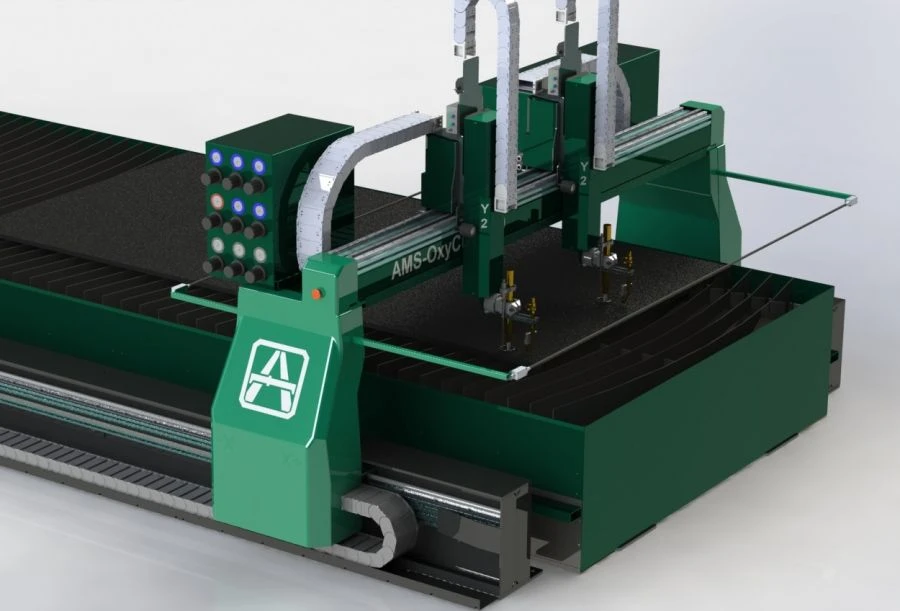

Thermal cutting machine "AMS-OxyCut"

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The thermal cutting machine "AMS-OxyCut" with CNC is designed for oxygen cutting of sheet metal according to the programme.

The width of the cutting zone of the machine can vary from 1.6 to 2.6 metres and the length of the cutting zone from 3.1 to 24.6 metres.

The design of the AMS-Combi thermal cutting machine:

- reliably protects the gantry and slide guides from any unintentional impact with foreign objects, from sparks and drops of molten metal;

- protects the gantry from heat radiation, preventing warping of the gantry beam and maintaining the accuracy of the machine geometrical parameters;

- ensures the safe presence of workers on the surface of the processed sheet (when preparing for cutting or when removing parts);

- torch holders are magnetically mounted with built-in collision sensors that block the machine operation in case of collision of the torch with a protruding part or other foreign object;

- allows up to 6 oxyfuel cutting slides to be accommodated.

The width of the cutting zone of the machine can vary from 1.6 to 2.6 metres and the length of the cutting zone from 3.1 to 24.6 metres.

The design of the AMS-Combi thermal cutting machine:

- reliably protects the gantry and slide guides from any unintentional impact with foreign objects, from sparks and drops of molten metal;

- protects the gantry from heat radiation, preventing warping of the gantry beam and maintaining the accuracy of the machine geometrical parameters;

- ensures the safe presence of workers on the surface of the processed sheet (when preparing for cutting or when removing parts);

- torch holders are magnetically mounted with built-in collision sensors that block the machine operation in case of collision of the torch with a protruding part or other foreign object;

- allows up to 6 oxyfuel cutting slides to be accommodated.

Specifications

Type of product according to PP RF 616

Universal

Power consumption

2...4 kW

Accuracy class

1; higher

Assignment

oxygen metal cutting

Type

oxygen cutting

Accuracy class

1

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Wire EDM machine ARTA 123 PRO

View Details

Installation for air-plasma cutting UVPR-120

View Details

Minimarker 2 C25 RA laser marking system

View Details

Laser marking, engraving equipment model GRAVER PORTAL

View Details

CNC plasma cutting machine of Plazmacroy trade mark Plazmacroy Master series model 6000

View Details

AMS-Combi" thermal cutting machine

View Details

Ritm-MA thermal cutting machine

View Details

Precision laser cutting machine MLP3

View Details

Wire EDM machine ARTA 423 PRO

View Details

Ritm-Laser laser cutting machine

View Details

LaserCut FO Standard series sheet metal cutting machines

View Details

Metal thermal cutting machine "ARIA MTRM 20/60"

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions