Available for Import

Available for Import

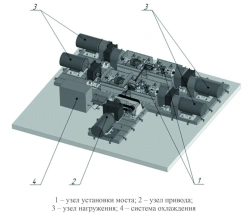

Test bench GAKS-I-3-10/300S

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

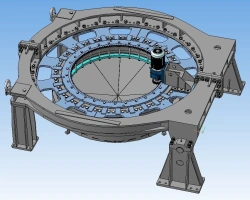

The test bench GAKS-I-3-10/300S is designed for pneumatic and hydraulic tests during adjustment (taring) of safety valves, for pneumatic tests on tightness of the gate of the adjusted valve and connection "body-saddle". Adjustment of valves on the stand is made by compressed air. The compressed air pressure is supplied and regulated to the bench from the pneumatic control panel. Gate tightness tests are carried out with high-pressure compressed air and technical water. Management and control of hydraulic tests, sealing of the valve by hydraulic clamping drive are carried out from the control panel of the pumping station. Measurement accuracy, logging of test results is achieved by using the electronic device "SEITRONIC PG10-1" or automated electronic system "SEITRONIC SIR-PG". The set of replaceable quick-installable plugs is determined by the nomenclature of the tested products.

Specifications

Type of product according to PP RF 616

Instruments and other instruments for measurement, control and testing

Application range by DN

10...300 (up to 400) mm

Maximum setting pressure Rn, MPa

20,0 (up to DN100); 16,0 (up to DN150); 9,6 (up to DN200); 6,3 (up to DN250); 4,0 (up to DN350); 2,5 (up to DN400)

Sealing of the valve under test

With hydraulic actuator

Maximum clamping force, tonnes

SBVVBG

Diameter of clamped flange, min/max, t

SBVVBG

Overall dimensions of the stand, mm

940x760x930 mm

Control methods used for pneumatic and hydraulic tests during valve setting

Manometric (by pressure drop in the inlet pipe of the valve) and acoustic (clear sharp popping sound when the adjusted valve is opened to the set pressure).

Control methods used for testing the tightness of the gate and body-to-seat connection

Visual (by presence/absence of air bubbles on the water surface in the outlet pipe)

Stand weight, kg

551 kg

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Test bench for testing driving axles for durability (TU 26.51.62-001-07549210-2024)

View Details

Transport trolley GAKS-KOB-T

View Details

Cylinder steaming unit GAKS-KOB-UP

View Details

Test benches (model IPG)

View Details

Test benches for mechanical seals of GAKS-I-7-11 type

View Details

Pneumatically controlled double-circuit pumping stations type GAKS-D-7

View Details

API-RP-61 (ISO 13503-5) proppant pack conductivity measurement apparatus - ITEK

View Details

GAKS-I-3 type test benches

View Details

Test bench for testing of rotary screw pivoting device of propeller columns SAPFIR

View Details

Automated universal complex of measurements and tests (AUKII)

View Details

Pneumatic test bench for cylinders with fittings GAKS-KOB-SP

View Details

Semi-automatic installation for hydro-testing of well equipment units

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions