Available for Import

Available for Import

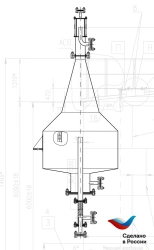

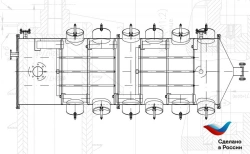

Technological line and equipment for production of alcohol, bioethanol (Bragg rectification unit BRU)

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

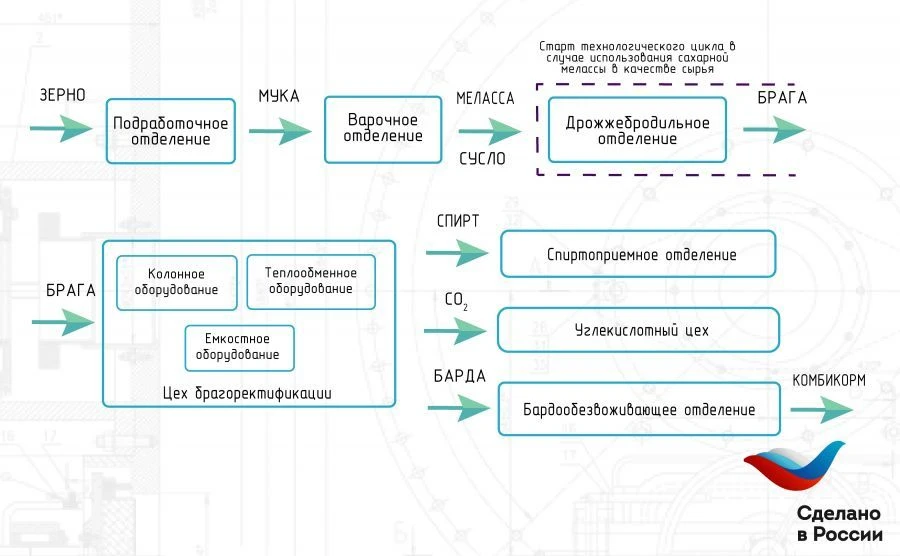

The braggorectification process line is designed for the production of alcohol and bioethanol.

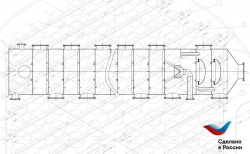

As an example, the description of the classical technological line of obtaining ethyl rectified food alcohol according to GOST R 51652-2000 on a seven-column indirect-acting braggorectification unit from starch-containing fermentation of raw materials is given.

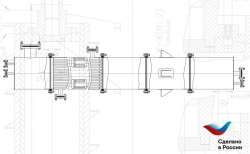

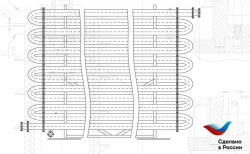

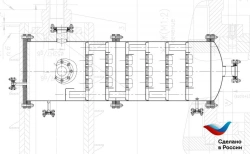

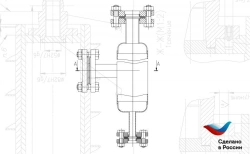

The liquor from the fermentation compartment is fed to the liquor sections of the liquor heater, where it is heated by the heat of water-alcoholic vapours coming from the liquor column. Then, the broth goes to the CO2 separator, to separate carbon dioxide and alcohol vapours, which go to the condenser of the CO2 separator, are condensed and sent to the distillation column.

The heated liquor from the CO2 separator flows through the odour trap to the feed plate of the distillation column, which is heated by acute steam. Saturated water-alcoholic vapours from the upper plate of the distillery column are fed to the distillery heater, from where, having partially condensed, they are directed to the feed plate of the epuration ... .

As an example, the description of the classical technological line of obtaining ethyl rectified food alcohol according to GOST R 51652-2000 on a seven-column indirect-acting braggorectification unit from starch-containing fermentation of raw materials is given.

The liquor from the fermentation compartment is fed to the liquor sections of the liquor heater, where it is heated by the heat of water-alcoholic vapours coming from the liquor column. Then, the broth goes to the CO2 separator, to separate carbon dioxide and alcohol vapours, which go to the condenser of the CO2 separator, are condensed and sent to the distillation column.

The heated liquor from the CO2 separator flows through the odour trap to the feed plate of the distillation column, which is heated by acute steam. Saturated water-alcoholic vapours from the upper plate of the distillery column are fed to the distillery heater, from where, having partially condensed, they are directed to the feed plate of the epuration ... .

Specifications

Line capacity

3000...40000

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Foam trap of LP grade

View Details

Epoetin of finished products V=0,01 cu.m.

View Details

Column with multi-cap plates KMT

View Details

Decanter

View Details

Column with sieve plates CCP

View Details

Absorption alcohol trap of SL grade

View Details

Steriliser tubular STET

View Details

Bard regulator of BAR brand

View Details

Multi-cap plate alcohol trap

View Details

Multi-cap sieve trap

View Details

OP brand vapour separator

View Details

Column with slotted plates D=1440 mm

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions