Available for Import

Available for Import

System MO-140

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The system of water treatment, water storage and water supply MO-140 is designed to purify water from open ponds, wells and boreholes from suspended solids, colloids, disinfection from bacteria and viruses, removal of iron compounds, manganese, copper, sulfur, phosphorus, organic substances (including petroleum products), dissolved salts, including compounds of one-, two- and polyvalent metals, storage of treated water and delivery of treated water under pressure to the consumer's water supply network (pumping station after the system is not required). The system can be used to supply water to individual houses with simultaneous residence of up to 12 people at a consumption rate of 250 litres/person per day.

If water is consumed only for drinking and cooking, the system can be used to supply water to up to 600 people.

The system consists of two units - a water treatment unit and a storage tank for purified water.

The equipment of the water treatment unit is mounted on a frame made of anodised aluminium machine profile equipped with vibration-isolating wheels. Pipelines of the water treatment unit are made of polypropylene pipes, electrical connections are made of polyamide corrugated pipe. All units with asynchronous electric motors are mounted on vibration supports.

The storage tank for purified water is made of food-grade polyethylene, equipped with a lid with a breathing valve, equipped with level relay electrodes and fittings for connection to the water treatment unit.

Water treatment technology. The initial water comes to the inlet of the high-pressure pump, and under pressure is supplied for treatment. Water is cleaned from mechanical impurities and dissolved organic substances (optionally, depending on the type of cartridges used) in the pre-filter, mixed with compressed air and delivered to the pressure aeration tank.

The pressurised air dissolves in the water. The dissolved oxygen interacts with the dissolved impurities on the surface of the catalytic backfill. Iron, manganese, ammonia and hydrogen sulphide are oxidised in the pressure aeration tank. The suspended solids formed during oxidation are retained by the catalytic backfill layer.

Periodically (at each filling up to the upper level of the treated water storage tank), the catalytic backfill is automatically washed with the reverse flow of treated water.

The treated water from the pressure aeration tank enters the post-filter, where suspended solids not captured in the catalytic backfill layer, wear products of the backfill, and dissolved organic matter adsorbed (optional, depending on the type of cartridges used) are removed.

The treated water then enters the nanofiltration membrane housing, where it is separated by the membrane into a desalinated permeate and a salt-enriched concentrate. The concentrate is discharged from the treated water block into the sewer. The concentrate is also discharged into the concentrate discharge line with the wash water from the pressure aeration tank.

The treated water passes through the permeate counter, is supplied with a preserving dose of sodium hypochlorite and enters the storage tank.

The treated water is pumped out of the storage tank by a purified water pump and fed into the consumer's water supply network and for flushing the catalytic backfill. For correct operation of the pump control system, a membrane tank is included in the purified water supply line.

If water is consumed only for drinking and cooking, the system can be used to supply water to up to 600 people.

The system consists of two units - a water treatment unit and a storage tank for purified water.

The equipment of the water treatment unit is mounted on a frame made of anodised aluminium machine profile equipped with vibration-isolating wheels. Pipelines of the water treatment unit are made of polypropylene pipes, electrical connections are made of polyamide corrugated pipe. All units with asynchronous electric motors are mounted on vibration supports.

The storage tank for purified water is made of food-grade polyethylene, equipped with a lid with a breathing valve, equipped with level relay electrodes and fittings for connection to the water treatment unit.

Water treatment technology. The initial water comes to the inlet of the high-pressure pump, and under pressure is supplied for treatment. Water is cleaned from mechanical impurities and dissolved organic substances (optionally, depending on the type of cartridges used) in the pre-filter, mixed with compressed air and delivered to the pressure aeration tank.

The pressurised air dissolves in the water. The dissolved oxygen interacts with the dissolved impurities on the surface of the catalytic backfill. Iron, manganese, ammonia and hydrogen sulphide are oxidised in the pressure aeration tank. The suspended solids formed during oxidation are retained by the catalytic backfill layer.

Periodically (at each filling up to the upper level of the treated water storage tank), the catalytic backfill is automatically washed with the reverse flow of treated water.

The treated water from the pressure aeration tank enters the post-filter, where suspended solids not captured in the catalytic backfill layer, wear products of the backfill, and dissolved organic matter adsorbed (optional, depending on the type of cartridges used) are removed.

The treated water then enters the nanofiltration membrane housing, where it is separated by the membrane into a desalinated permeate and a salt-enriched concentrate. The concentrate is discharged from the treated water block into the sewer. The concentrate is also discharged into the concentrate discharge line with the wash water from the pressure aeration tank.

The treated water passes through the permeate counter, is supplied with a preserving dose of sodium hypochlorite and enters the storage tank.

The treated water is pumped out of the storage tank by a purified water pump and fed into the consumer's water supply network and for flushing the catalytic backfill. For correct operation of the pump control system, a membrane tank is included in the purified water supply line.

Specifications

Peak water flow rate from the storage tank

1.8

Dry weight of water treatment unit

102 kg

Installed electrical capacity of the system

1.65 kW

Source water path vacuum at the system inlet

0.05 MPa

Source water pressure at the system inlet

0.4 MPa

Ambient temperature during storage and operation

5...40 °C

Life before overhaul

1000

Assigned resource

8000

Dimensions of the treated water tank DxW

not more than: 540?1880 mm

Dimensions of the water treatment unit LxWxH

Not more than: 500x500x1800 mm

Capacity for purified water

400 l/h

Power supply 220 V

SBVVBG

Power supply (380 V)

SBVVBG

Average drainage water flow rate

max: 200 l/h

Average treated water capacity1

not less than: 140 l/h

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

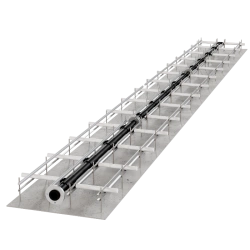

Aerating system of comb type AerS

View Details

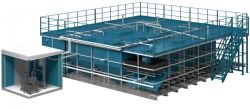

System O-10000

View Details

LOS-R model wastewater treatment plant

View Details

Installation of M-160

View Details

Drinking water treatment plant AEROMAG-500

View Details

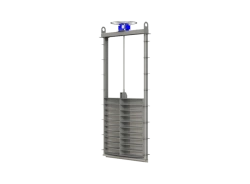

Shield gate Vökker FR-3R-P1 400x400

View Details

Compact physical-chemical treatment unit Flotator FT series

View Details

Complete mechanical wastewater treatment plant VÖKKER IMC- PV100-CR08-VM2500

View Details

Aeration system

View Details

System MO-50000

View Details

Bar grating with back rake RP

View Details

Storm (surface) waste water treatment facility "AGMA-LOS" series

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions