Available for Import

Available for Import

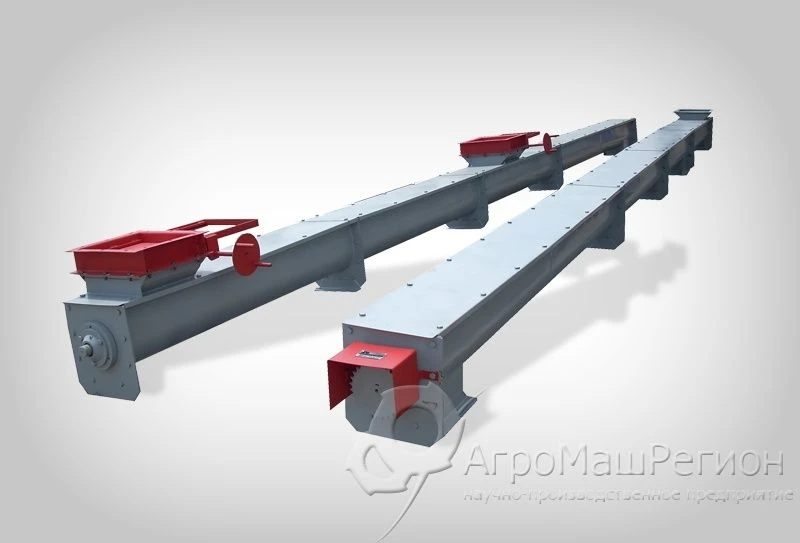

Stationary screw conveyor type UHT model UHT - 250-01

Bulk pricing available

FOB, CIF & EXW terms available

Available Models

Description

Conveyor screw stationary is designed for transporting grain and its products. The conveyor provides cargo movement in a horizontal position and at an incline (not more than 45 degrees). The components of the conveyor are the initial (loading) link, the final (unloading) link with the installed drive, the middle link (depending on the length of the conveyor different number), the level sensor.

The principle of operation of the conveyor is as follows: the product getting into the chute with a rotating screw, under the influence of pressure forces on it makes a movement along the axis of the chute. The load cannot rotate together with the screw as it is prevented by the friction force against the pipe and its own weight. The conveyor is loaded through an opening in the chute.

The product is discharged from the conveyor through the discharge window located at the bottom of the chute. There can be several discharge windows and all of them must be regulated by gate valves.

Specifications

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Screw Conveyors Type UKV - Customizable Design

View Details

Screw Conveyor for Food Transportation and Packaging

View Details

Stationary Screw Conveyor for Grain and Processed Products UVT-250

View Details

Screw Feeders for Grain and Bulk Materials - USH, UKV Models

View Details

R1-BKSH-160 Screw Conveyor for Grain Transport

View Details

Screw Feeder for Uniform Material Transport

View Details

Stationary Screw Conveyor for Grain Transportation

View Details

Screw Feeders Type 2PSH for Bulk Material Transport

View Details

Screw Feeders for Bulk Materials Transportation, Type EC

View Details

Mobile Screw Conveyor for Grain Transport - KPVS-250-2 (Self-Feeding)

View Details

Screw Feeders PSh and PShV - Uniform Material Transport

View Details

Screw Feeders 4PSH for Bulk Material Transport

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions