Available for Import

Available for Import

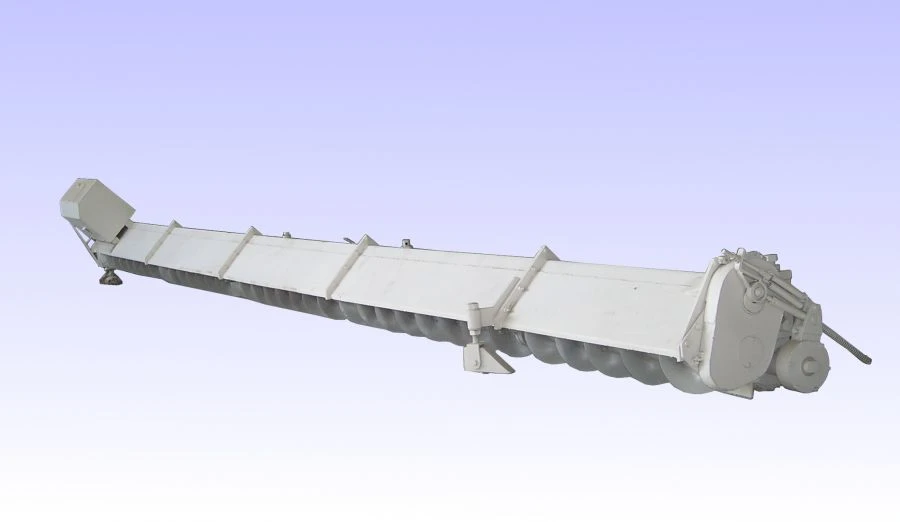

ShZ type stripping augers for food industry (types ShZ-6 - ShZ-32, ShZ-14a - ShZ-32a)

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The stripping auger is used at the enterprises of the system of bakery products, for unloading of grain and its products from metal silos with flat bottom.

Cleaning auger consists of the following parts: auger, formed by a spiral surface welded to the tubular shaft, the mechanism of auger movement on a circle, the mechanism of rotation of the auger itself, protective casing, housing. It is equipped with a current collector excluding cable laying inside the silo, torque limit couplings providing uniform and smooth operation of the auger, as well as excluding reverse running of the auger. The stripping auger is installed in the centre of the silo.

Operating principle: After the main unloading of grain from the silo by means of unloading funnels, the stripping auger is put into operation for unloading of grain residues. Moving in a circle inside the silo, the auger transports the grain to the centre hopper. The auger is rotated by a gear motor.

The main advantages of stripping augers manufactured by Sevkavelevators Corporation Ltd....

Cleaning auger consists of the following parts: auger, formed by a spiral surface welded to the tubular shaft, the mechanism of auger movement on a circle, the mechanism of rotation of the auger itself, protective casing, housing. It is equipped with a current collector excluding cable laying inside the silo, torque limit couplings providing uniform and smooth operation of the auger, as well as excluding reverse running of the auger. The stripping auger is installed in the centre of the silo.

Operating principle: After the main unloading of grain from the silo by means of unloading funnels, the stripping auger is put into operation for unloading of grain residues. Moving in a circle inside the silo, the auger transports the grain to the centre hopper. The auger is rotated by a gear motor.

The main advantages of stripping augers manufactured by Sevkavelevators Corporation Ltd....

Specifications

Screw length

3946...16035 mm

Grain capacity (at grain density 075 t/m3, moisture content 14%)

100...500

Screw diameter

250...600 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

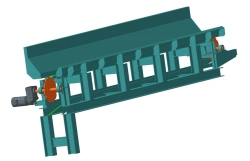

Interoperative disc conveyor model TDM (and its modifications)

View Details

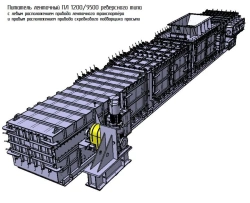

Belt Feeder PL 1200/9500

View Details

Universal belt conveyor TPL-U

View Details

AXEL Log Receiving and Stretcher 04-1

View Details

Feeding conveyor TP

View Details

10-11 AXEL longitudinal measuring and evaluating log sorting conveyor of log sorting/feeding line

View Details

Longitudinal AXEL 10-13 Log Receiving, Measuring and Evaluation Conveyor

View Details

Chain conveyor, type K

View Details

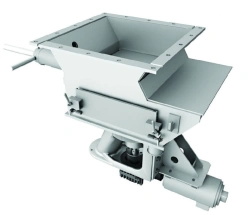

Paddle dust feeder

View Details

AKSEL wood feeding line

View Details

05-1 Longitudinal receiving conveyor of AXEL log sorting/feeding line

View Details

Receiving cross table log conveyor

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions