Available for Import

Available for Import

Shaft electric furnace SHZ 6.6/7 STC

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

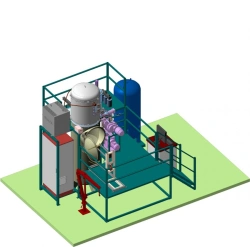

Purpose: Tempering, annealing of metals and alloys.

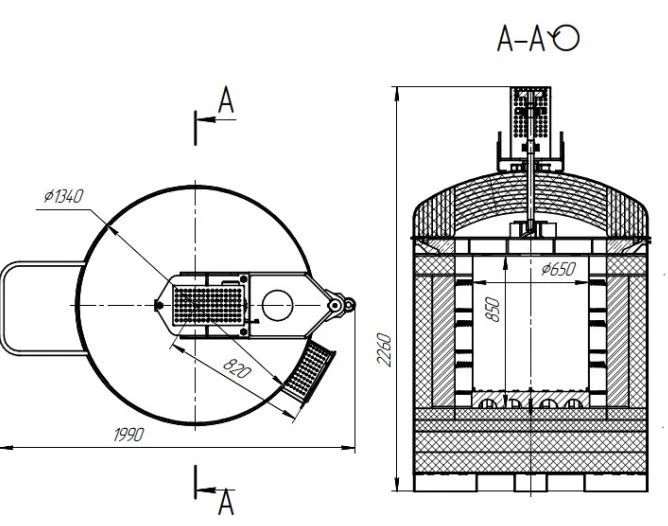

Design features: The control system cabinet is included. The body of the furnace is made of rolled steel sheet. The furnace lid is equipped with a mechanised drive for lifting, and the outlet to the side - manually. The oven is equipped with an air circulation system. The heaters are located on the side walls. Lining material for walls and lid with low heat accumulation and low thermal inertia. Accelerated heating up of the furnace to operating temperature and low inertia transition from one mode to another. Service life (without mechanical damage): heaters, not less than 5 years; linings, not less than 10 years.

Advantages: Increased energy efficiency and energy saving during operation. Increase of inter-repair period and service life of heaters and lining. Increase in the yield of finished products.

Technical Specifications

| Type of product according to PP RF 616 | Electric resistance furnaces |

|---|---|

| Mark | SSHZ 6.6/7STC |

| Furnace type | Shaft SSZ 6.6/7 |

| Workspace size (Diameter x Height) | 600 x 600 mm |

| Overall dimensions | 1580 ? 1790 ? 2895 |

| Maximum operating temperature | 700 °C |

| Number of heating zones | 1 pc |

| Heater power | 45 kW |

| Supply mains voltage | 380 V |

| Mains frequency | SBVVBG |

| Number of phases | 3 pc |

| Atmosphere in the furnace workspace | air |

| Furnace operation mode | 600 hours per year, continuous-cyclic schedule |

| Cage weight | 650 kg |

| Type of climatic version of the furnace | UHL 4.1 GOST 15150-69 |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

Hooded hydrogen electric resistance furnace type SGZ

View Details

Hydrogen elevator hydrogen resistance electric furnace type SENE

View Details

Shaft resistance electric furnace of SSHTSM type

View Details

Electric chamber resistance furnace SNOT

View Details

Electric furnace unit for heat treatment elevator quenching, model ????

View Details

Vacuum chamber electric resistance furnace SNVE-2.4.2/16

View Details

Electric resistance chamber furnace with oxidising atmosphere, model SCOS

View Details

Horizontal vacuum sintering furnace DO-5,5.5.12,5.5,5-17TT-VT

View Details

Vacuum electrothermal plant KB 155

View Details

Elevator vacuum double-chamber electric resistance furnace for hardening D-2,2,E-13,5UT-IVT-M

View Details

Laboratory electric furnace PL 5/12,5

View Details

Shaft resistance electric furnace SSZ

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions