Available for Import

Available for Import

Rail-laying complex RU-700

Manufacturer:

Tulazheldormash OJSC im. A.V. Silkina

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Available Models

Description

Performance of works on change of rail shoulders with their introduction into the optimum temperature interval of fixing and replacement of under-rail gaskets.

Rail-laying complex RU-700 is designed to perform works on changing of old rails or inventory rails assembled in the stubs to new rail stubs with their introduction into the optimal temperature interval of fixing or to the assembled rails with overlays and replacement of under-rail gaskets.

-Performance of a complex of track works on change of rail straps, under-rail pads and introduction of straps into the fixing temperature in one pass;

-Reduction of the number of personnel involved in carrying out the works

-Elimination of the human factor when carrying out the work on heating of the rail shoulders

-Fixing of key parameters of performed works in the machine memory

-Enhancement of work culture

Rail-laying complex RU-700 is designed to perform works on changing of old rails or inventory rails assembled in the stubs to new rail stubs with their introduction into the optimal temperature interval of fixing or to the assembled rails with overlays and replacement of under-rail gaskets.

-Performance of a complex of track works on change of rail straps, under-rail pads and introduction of straps into the fixing temperature in one pass;

-Reduction of the number of personnel involved in carrying out the works

-Elimination of the human factor when carrying out the work on heating of the rail shoulders

-Fixing of key parameters of performed works in the machine memory

-Enhancement of work culture

Specifications

Type of product according to PP RF 616

Machines for compaction, straightening, shoring and straightening of tracks

Productivity (speed of replacement of P65 rails with heating and change of under-rail gaskets)

700

Temperature difference of rail before and after heating

SBVVBG °C

Number of sections, pcs.

2 pcs

Speed during transportation in a train

80

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Portable Autonomous Sleeper Tamper with Diesel Drive SHPVD

View Details

Primary Railway Alignment Machine MPV-2000

View Details

Railway Straightening and Leveling Machine VPRS-03.2

View Details

Hydraulic Rail Straightener RGU-4M

View Details

Universal Track Repair Machine MPRU(R) for Railway Maintenance

View Details

Ballast Stabilization and Finishing Machine VPO-C

View Details

Universal Repair Track Machine MPRU

View Details

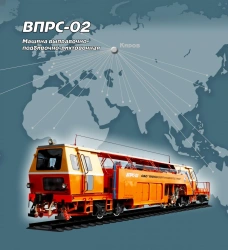

Railway Track Straightening and Tamping Machine VPRS-02M

View Details

Electric Vibratory Ballast Tamper SHPVE-2M

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions