Available for Import

Available for Import

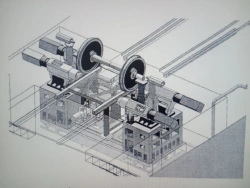

Numerically controlled metalworking lathe-milling machine ITS 250/1000

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

1.The machine is designed for cold working of metal.

2.Machine tools are designed for turning cylindrical (with a straight, stepped and curved profile), tapered and end surfaces on parts such as bodies of rotation, as well as for cutting threads: metric, modular, inch, pitchevoy and pipe tapered.

3.Processed materials: ferrous and non-ferrous metals, cast iron, plastic.

4.The machine is equipped with a CNC (numerical control) device, which minimises the operator's participation in the process of processing the part.

5.The machine is designed for 2-shift work.

6.Accuracy resource up to the first average repair-12 thousand hours

7.Service life of the machine tool is 5 years.

8.The machine has a rigid bed, on the guides of which moves the slide and tailstock (Z-axis). On the guides of the slide carriage moves the slide with a 4 or 8-position turret mounted on it (X-axis). The left y...

Technical Specifications

| Type of product according to PP RF 616 | Numerically controlled metal turning machine tool |

|---|---|

| Type | Numerically controlled metal turning machine tool |

| Accuracy class according to GOST 8-82 | ? |

| Largest workpiece Ø for turning above the bed | 600 mm |

| Maximum workpiece Ø when turning above the slide | 250 mm |

| Largest size of workpiece to be inserted in a chuck with back centre clamping | 1100 mm |

| Largest dimension of the cutting zone in the chuck with back-centre clamping. | 960 mm |

| Largest dimension between spindle face and tailstock quill face (without chuck and tailstock centre) | 1300 mm |

| Maximum longitudinal travel with tailstock | 980 mm |

| Longest stroke of transverse movement | 340 mm |

| Highest weight of the product to be installed in the chuck | 300 kg |

| Maximum weight of the workpiece to be installed in centres | 1500 kg |

| Working feed rate limits in X, Z axes | 4000 |

| X-axis rapid traverse speed 1098469:X-axis rapid traverse speed | 10000 |

| Z-axis rapid traverse speed | 20000 |

| Discreteness of motion setting in all axes | 1 |

| Single-sided positioning accuracy in the X axis | 3 |

| Single-sided positioning accuracy in the Z axis | 5 |

| Repeatability of positioning in X and Z axes | 3 |

| Spindle bore diameter | 55 mm |

| Main drive motor power | 15 kW |

| Highest torque on the spindle | 250 |

| Spindle speed limits | 4000 |

| Spindle speed control | stepless |

| Diameter of clamping chuck | 250 mm |

| Clamp type | Manual |

| Diameter of tailstock quill | 75 mm |

| Rear headstock quill travel | 150 mm |

| Tailstock quill clamping | Manual |

| Locking of the tailstock | manual |

| Cooling system capacity | Built-in memory card slot, support microSD/SDHC/SDXC card (up to 256GB); manual recording/alarm recording l |

| Cooling system pressure | 5 |

| Type of mains current | AC, three-phase |

| Current frequency | SBVVBG |

| Power supply voltage | 380 V |

| Control circuits | 24 V |

| Local lighting circuits | 24 V |

| Length of overall machine with chip conveyor | 5243 mm |

| Overall width of the machine with main console | 2125 mm |

| Overall height of the machine with machine supports | 1793 mm |

| Machine weight | 3620 kg |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

CNC lathe model STR30

View Details

Used CA500C10F2 lathe with OSU

View Details

CNC Tube Lathe with rolling guides CAT700C08F3(T) incl.

View Details

Special CNC wheel lathe model RT906F3

View Details

Centre lathe 1525F1.400

View Details

Horizontal CNC lathe of "Proton T" type Proton T500K model

View Details

MT-210 CNC Turning Centre

View Details

CNC slitting machine, model IZH Caliber 20

View Details

CNC LATHE NT250C05F3

View Details

Lathe with LSU CA600C30F2

View Details

Lathe machining centre with 1000mm Face Centre Model 1715Y-2D-1

View Details

CNC lathe CA1000C40F3K

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions