Available for Import

Available for Import

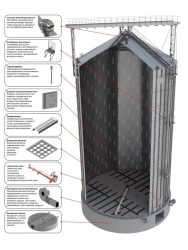

Metal silo with cone bottom (with vibrating activator) SKVA242-2-5,6-7-VAB-1250

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Available Models

Metal silo with cone bottom (with vibrating activator) SKVA269-2-5,6-8-VAB-1250

Metal silo with cone bottom (with vibrating activator) SKVA160-2-5,6-4-VAB-1250

Metal silo with cone bottom (with vibrating activator) SKVA503-2-6,4-12-VAB-1250

Metal silo with cone bottom (with vibrating activator) SKVA187-2-5,6-5-VAB-1250

Metal silo with cone bottom (with vibrating activator) SKVA467-2-6,4-11-VAB-1250

Description

Purpose:

The silo is designed for short-term storage of hard-to-flatten products prone to lumping, such as meal, bran, mixed fodder, filter attitudes, waste from bunker silos, various granulated products with volumetric mass up to 800 kg/m3. Provides uniform unloading of the product. It is used as a part of lines on manufacture of mixed fodders for short-term storage of a product before its processing, and also as a container of temporary storage of already ready product. The silo can be used as a container for temporary storage of waste from grain cleaning machines, local filters, dust collectors and other similar devices.

Advantages:

1. The silo is supplied as a complete set with a vibrating unloader.

2. The silo comes complete with membrane type sensors to measure the upper and lower levels of the product.

3. Uniform discharge of the product from the silo is organised with the possibility to regulate the productivity (due to the displacement of the balancer weights).

4. The silo design is designed for the loads of regions with high precipitation: 5 snow region (320 kg/m2) and 2 wind region (31 kg/m2 (80km/hour)), which is superior to imported technologies in terms of withstanding loads.

5. Silo design prevents water and snow from entering the silo interior.

6. The reinforced silo design is designed to withstand additional dynamic loads.

7. Sampling point to monitor product condition.

8. The silo is made of corrugated galvanised sheets of high-strength rolled metal with galvanising depth not less than 450 gr/m2 with external stiffening ribs.

9. The silo is assembled with high-strength bolts of strength class 8.8 and 10.9 with plastic washers to ensure tightness and strength of the silo.

10. Laser markings on the parts and instructions with 3D views speed up and facilitate silo assembly.

The silo is designed for short-term storage of hard-to-flatten products prone to lumping, such as meal, bran, mixed fodder, filter attitudes, waste from bunker silos, various granulated products with volumetric mass up to 800 kg/m3. Provides uniform unloading of the product. It is used as a part of lines on manufacture of mixed fodders for short-term storage of a product before its processing, and also as a container of temporary storage of already ready product. The silo can be used as a container for temporary storage of waste from grain cleaning machines, local filters, dust collectors and other similar devices.

Advantages:

1. The silo is supplied as a complete set with a vibrating unloader.

2. The silo comes complete with membrane type sensors to measure the upper and lower levels of the product.

3. Uniform discharge of the product from the silo is organised with the possibility to regulate the productivity (due to the displacement of the balancer weights).

4. The silo design is designed for the loads of regions with high precipitation: 5 snow region (320 kg/m2) and 2 wind region (31 kg/m2 (80km/hour)), which is superior to imported technologies in terms of withstanding loads.

5. Silo design prevents water and snow from entering the silo interior.

6. The reinforced silo design is designed to withstand additional dynamic loads.

7. Sampling point to monitor product condition.

8. The silo is made of corrugated galvanised sheets of high-strength rolled metal with galvanising depth not less than 450 gr/m2 with external stiffening ribs.

9. The silo is assembled with high-strength bolts of strength class 8.8 and 10.9 with plastic washers to ensure tightness and strength of the silo.

10. Laser markings on the parts and instructions with 3D views speed up and facilitate silo assembly.

Specifications

Overall dimensions

5573 mm

Hatch height

1700 mm

Model

????242-2-5,6-7-???-1250

Type

with cone bottom (with vibration activator)

Metal thickness

1...3 mm

Diameter

5573 mm

Scope

242

Capacity

194 t

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Capacitive vessels and apparatuses

View Details

Ventilated metal silo unified flat-bottom SMP.275

View Details

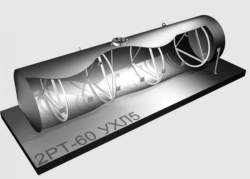

Steel single-walled horizontal cylindrical tank type 2RT - 60

View Details

Flat-bottomed metal silo SP6036-21,78/16

View Details

Metal silo with cone bottom (with vibrating activator) SKVA269-2-5,6-8-VAB-1250

View Details

Horizontal steel tanks RGS

View Details

Water tower VBR-50

View Details

Welded steel tank apparatuses

View Details

Horizontal steel underground tank RGSP-50

View Details

Horizontal steel underground double-walled tank 60 m3 type RGSPD-60

View Details

Metal water tanks

View Details

Horizontal steel tank 15 m3 of RGS-15 type

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions