Available for Import

Available for Import

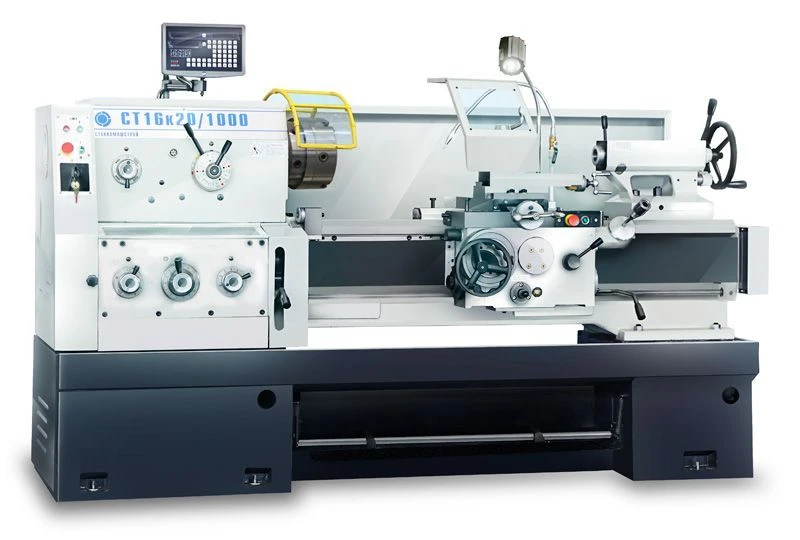

Metal-cutting lathe without numerical programme control ST16K20/1000

Bulk pricing available

FOB, CIF & EXW terms available

Description

Metal-cutting lathe without numerical control series ST16K20/1000 produced by StankoMashStroy, are modern, upgraded analogues of the Soviet machine 16K20 and can be used in various industries in all kinds of operations for processing different materials: turning and boring of cylindrical and tapered surfaces; cutting external and internal metric, inch, modular, pitch threads; drilling, countersinking, reaming. The strong design of the cast bed and its hardened, hardened and ground guides ensure professional machining and reliable stable operation. The spindle supports are fitted with high precision bearings, which means that the spindle unit and the overall rigidity of the machine are increased. This enables machining with high cutting forces and full utilisation of the drive power. The machines are high-tech and easy to operate.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Horizontal Axis Resonance Balancing Machine VM-1000

View Details

Precision Lathe Machine 16K40F1 for Diverse Turning Operations

View Details

High-Speed CNC Dual-Spindle Front Chuck Lathe MP315

View Details

Precision Lathe Machine for Turning and Threading RT817F1-1

View Details

Universal Lathe Machine for Turning and Thread Cutting 16K40PF1-1

View Details

Precision Lathe Machine for Turning and Threading RT317F1-13

View Details

Compact Universal Lathe-Tapping Machine TV-7M

View Details

High Precision Wire EDM Machine DIPOL350F03

View Details

Precision Lathe Machine RT817F1-3 for Turning and Threading

View Details

Precision Lathe Machine RT817 for Various Turning Applications

View Details

Special Turning Machine RT117

View Details

Universal Lathe and Screw-Cutting Machine Samat 400 XV

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions