Available for Import

Available for Import

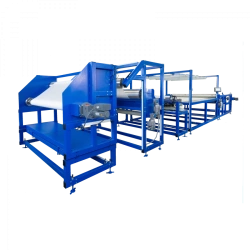

Measuring and packing machine mod. B02.4 for elastic and non-elastic materials, including knitted fabrics.

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

The machine provides rewinding of material rolls with diameter up to 400 mm and weight up to 60 kg. Available in roll widths from 1800 mm/ up to 2000 mm/ up to 2500 mm/ up to 3200/ up to 3500 mm. Standard equipped with roll edge levelling system, double material stretch tracking system, electronic programmable metre counter, forward and reverse stroke with twisting into a roll, viewing screen with LED backlight, roll end sensor, etc. The machine can be additionally equipped with additional overhead lighting, device for static removal, density adjustment of the winding of the bale, cutting manual or automatic knife, ruler for visual measurement of the width of the material, Astra software for the accounting of scrapped materials, weighing system of the winding bale, adjustment of the....

Technical Specifications

| Mark | Rolltex |

|---|---|

| Maximum bale diameter | 400 mm |

| Maximum bale weight | 60 kg |

| Electronic programmable counter for material length measurement | The electronic meter meter allows you to: use conversion factors that allow you to increase the accuracy of measuring materials of different densities and stretching; - non-volatile power supply of the meter ensures the preservation of the worked |

| Automatic material stretch tracking system | Double material stretch control function, provides rewinding and metre measurement of delicate materials and knitted fabrics. |

| Automatic bale edge equalization system | function ensures that the edge of the material roll is aligned to the base side (except for curled edge webs). |

| View screen | Viewing screen is equipped with LED backlight. viewing screen height is 560 mm. viewing screen tilt angle is 70º. |

| Touch screen rotary operator panel | the machine is controlled from the operator's touch panel, which is designed in Russian. |

| Foot-operated rear and front foot controls | The foot pedal is necessary for easy filling of the machine. the rear pedal switches on the drives of the unwinding rollers. the front pedal is used for switching on and off the drives in the machine in case of defects or other technological reasons. |

| Rewinding scheme | from a cylindrical roll wound on a cardboard bobbin into a cylindrical roll wound on a cardboard bobbin with an outer diameter of at least 40 mm. |

| Reverse (Reverse) | The backstroke function is used for rewinding back the material in case of a missed/clarified defect or if the residual material has been rewound into a roll. |

| Machine stop sensor at the end of the bale | the bale end sensor is necessary to increase the measuring accuracy. upon opening the bale end sensor, the machine resets the rewind speed to 5 m/min and the operator finishes the rewind at a low rewind speed. |

| Additional unwinding axis for handling non-cylindrical bales on the cardboard bobbin inside | The axle is necessary for working with non-cylindrical bales on the bobbin. when using the "axle rewind" function, the machine automatically switches off the drive of the unwinding rollers in order to save energy consumption. |

| Overall dimensions (length x width), mm for machine with bale width up to 1800 mm | 1600x2500 |

| Maximum electrical power consumed by the machine | 7 kW |

| Mains power supply | 220 V |

| Passport, operating and maintenance instructions | supplied with equipment |

| Maximum material width | 1800 mm |

| Rewind speed | Rewind speed is infinitely variable from 0 to 50 m/min. |

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Shipping & Payment Information

Shipping Terms

- FOB: Novorossiysk, Russia

- CIF: Available to major ports worldwide

- EXW: Manufacturer's facility, Russia

Delivery Time

- Sea freight: 30-60 days (depending on destination)

- Air freight: 14-21 days (for urgent orders)

- Production lead time: 30-90 days (depending on order size)

Payment Methods

- Letter of Credit (L/C)

- Wire Transfer (T/T)

- Escrow Services

Order Minimums

- We work with orders starting from 1 container

- You can mix different products in one container

- Volume discounts available for larger orders

Customs & Documentation Support

We provide comprehensive assistance with all export documentation, customs clearance, and logistics arrangements. Our team has extensive experience facilitating international trade with businesses in Africa, Middle East, Asia, and Latin America.

Contact Our Import Specialists

WhatsApp (Recommended)

For fastest response and immediate assistance with pricing, availability, and ordering.

+971 58 657 4796For detailed inquiries, documentation requests, and formal communications.

Send Email Inquiry info@tonzar.comRequest Call Back

Schedule a consultation with our import specialists at your convenience.

Business Hours

We're available to assist you during the following hours:

- Monday - Friday: 9:00 AM - 6:00 PM (GMT+4)

- Saturday: 10:00 AM - 2:00 PM (GMT+4)

- Sunday: Closed

Our WhatsApp support is available outside business hours for urgent inquiries.

Similar Products You May Be Interested In

Ironing table LGS-103.34

View Details

Measuring and rejecting machine A02

View Details

Measuring and rejecting machine A02.5, material width up to 2000 mm

View Details

Measuring and bagging machine with a unit for cutting off the edges of carbon fabrics and carbon mats mod. B02.35

View Details

Nonwovens measuring and doubling machine model C02.2 for nonwovens for rolls up to 4200 mm wide

View Details

Rolltex bale slitting machine mod. B03.2

View Details

Measuring and bagging machine (3 metre long measuring table) mod. B01.31 for non-elastic and slightly elastic materials

View Details

VK-2450P ironing calender

View Details

Ironing table LGS-159.12

View Details

Ironing roller VG-2030

View Details

VK-2250 ironing calender

View Details

Measuring and bagging machine mod. B02.14

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions