Available for Import

Available for Import

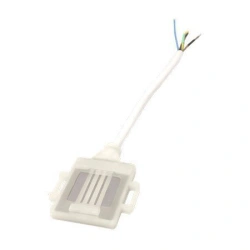

MAGNETIC-VORTEX FLAW DETECTOR VIEW-345

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The device is designed to detect and determine the depth of cracks in metal structures; to measure the thickness of the insulation coating on the controlled product.

The combination of magnetic and eddy current methods of defect detection allows to work:

- on rough, corroded surface (pipes, structural parts);

- on wet, dirty surfaces;

- on surfaces with variable thickness of insulation coating without additional adjustment.

Objects of control:

- Parts of structures, machines and mechanisms

- Pipes, pipelines, oil and gas pipelines

- Pressure vessels

- Objects of energy production

Advantages in operation:

- During the scanning process, the mode of crack search (including stress-corrosion cracks) with simultaneous determination of their depth and control of insulation and/or corrosion thickness (assumed to be max. 4 mm) operates.

- Crack search is carried out with insulation thickness up to 10 mm.

- Detection of corrosion sores under the insulation coating.

The combination of magnetic and eddy current methods of defect detection allows to work:

- on rough, corroded surface (pipes, structural parts);

- on wet, dirty surfaces;

- on surfaces with variable thickness of insulation coating without additional adjustment.

Objects of control:

- Parts of structures, machines and mechanisms

- Pipes, pipelines, oil and gas pipelines

- Pressure vessels

- Objects of energy production

Advantages in operation:

- During the scanning process, the mode of crack search (including stress-corrosion cracks) with simultaneous determination of their depth and control of insulation and/or corrosion thickness (assumed to be max. 4 mm) operates.

- Crack search is carried out with insulation thickness up to 10 mm.

- Detection of corrosion sores under the insulation coating.

Specifications

Dimensions of the standard sensor

25 x 25 x 60 mm

Dimensions of flaw detector electronic block

150 x 80 x 35 mm

Type of product according to PP RF 616

Instruments and other instruments for measurement, control and testing

Continuous battery operation time

10

Minimum depth of detectable fracture

0.2...0.5 mm

Minimum length of crack to be detected

5 mm

Minimum crack opening

0.05 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Digital radiography complex "TsiRKom-6852-50"

View Details

High-voltage circuit breaker monitoring device PKV/U3.0 (its modification PKV/U3.1)

View Details

ULTRASONIC HARDNESS TKM-459S HARDNESS TESTER

View Details

CCA 32.008-09 No.1 non-destructive testing measure

View Details

Set of transducers for USK-5A-2 (additional)

View Details

Cable No. 26

View Details

Set of transducers for USO-1A-1 (additional)

View Details

Stationary X-ray installation for personal search of a person "PERSONA-SCAN".

View Details

ELECTROPOTENTIAL CRACK GAUGE 281M

View Details

Correlation leak detectors of "ISKOR" series

View Details

Block of plate-indicator ZGANS BPI-2

View Details

Converter P111-5-12T for Altec AT-17

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions