Available for Import

Available for Import

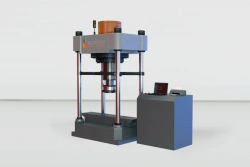

Machines for testing abrasive wheels mod. CIP800K1L

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The machine consists of a bed, drive, two spindle heads, small and large test chambers and electrical equipment.

The spindle heads and drive are mounted on the bed.

The abrasive wheels are mounted on the spindles of the small and large test chambers by means of sleeves, flanges and spacer sleeves and secured with nuts.

The spindles of the large and small chambers are driven by electric motors via belt drives.

Spindle rotation is separate.

The spindle speed is set by means of a remote control panel. The machine is controlled by a programmable logic controller with touch panel operator and a frequency converter from Delta Electronics.

The operator has options to parameterise the tear test cycles of the grinding wheel. The operator panel also displays diagnostic and alarm messages.

The spindle heads and drive are mounted on the bed.

The abrasive wheels are mounted on the spindles of the small and large test chambers by means of sleeves, flanges and spacer sleeves and secured with nuts.

The spindles of the large and small chambers are driven by electric motors via belt drives.

Spindle rotation is separate.

The spindle speed is set by means of a remote control panel. The machine is controlled by a programmable logic controller with touch panel operator and a frequency converter from Delta Electronics.

The operator has options to parameterise the tear test cycles of the grinding wheel. The operator panel also displays diagnostic and alarm messages.

Specifications

Type of product according to PP RF 616

Industrial control and measuring machines

Model

SIP800K1L

Maximum working speed of the wheel Vs, not more

63

Outer diameter of wheel

150...800 mm

Maximum height of the wheel

200 mm

Number of spindles

1 pc

Количество испытательных камер

1 pc

Test run speed Vpr*

42...96

Limit spindle speed nmax

10000

Spindle speed control

stepless

Transmission of rotation to spindle

Polycotton

Loading and unloading of test laps

manual

Lap test cycle in mode

automatic

Electric motor

AIR132M4

Power

11 kW

Rotational speed

1500

Machine dimensions

1510x1200x1650 mm

Machine weight

1350 kg

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Apparatus for determination of sinterability index and Horn index.

View Details

Electrohydraulic testing press PI-IX (up to 2000 kN)

View Details

Rockwell hardness tester TR 5018M Tochline

View Details

Brinell hardness tester TB 5015-01C Tochline

View Details

Universal testing machine REM-I-5-M

View Details

Vickers hardness tester TV 5214A-50 Tochline

View Details

Micro hardness tester TVM 5215C Tochline

View Details

Universal testing machine REM-I-0,5

View Details

Universal testing machine REM-I-0,1-M

View Details

Rockwell hardness measuring instrument TR 5014-01M

View Details

Universal hardness tester UT 5021PA Tochline

View Details

Brinell hardness tester TB 5005A Tochline

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions