Available for Import

Available for Import

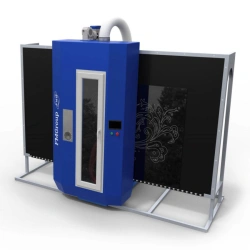

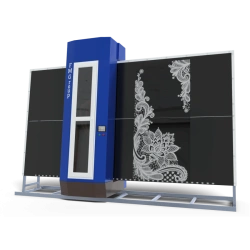

Injector type chamber KSO-100-I-SF-R

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

The chamber is designed to work in closed rooms.

The chamber is designed for cleaning, removal of rust, sand and scale, obtaining the necessary roughness, removal of layers, matting, hardening, deburring and polishing, as well as for the preparation of surfaces before the application of anti-corrosion coatings (lacquers, metallisation coatings).

The chamber is equipped with a system for removal of polluted air from the working area and its cleaning, with simultaneous cleaning of abrasive material from large inclusions and dust.

The chamber provides high quality of processing when using any abrasive material of the required fraction and hardness.

When using the same abrasive material and with the same nozzle, the productivity of the blasting process increases with increasing pressure and compressed air flow rate.

The chamber is designed for cleaning, removal of rust, sand and scale, obtaining the necessary roughness, removal of layers, matting, hardening, deburring and polishing, as well as for the preparation of surfaces before the application of anti-corrosion coatings (lacquers, metallisation coatings).

The chamber is equipped with a system for removal of polluted air from the working area and its cleaning, with simultaneous cleaning of abrasive material from large inclusions and dust.

The chamber provides high quality of processing when using any abrasive material of the required fraction and hardness.

When using the same abrasive material and with the same nozzle, the productivity of the blasting process increases with increasing pressure and compressed air flow rate.

Specifications

Working pressure

0.35...0.7 MPa

Compressed air flow rate, cubic meters per minute

0.2...1.2

Capacity, square meter per hour

1...3

Lightweight abrasive material, fraction up to

1.5 mm

Steel abrasive material, fraction up to

0.3 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Sandblasting machine RPU-2 for glass and mirror

View Details

Set for equipment of abrasive blasting area with vacuum system of transport and recovery of abrasive ma

View Details

Installation of hydro-abrasive treatment (cleaning) "KS-100"

View Details

Automated sandblasting machine 1-1,2 cbm/min 0,6-0,8 mPa

View Details

Pressure blast machine VMZ®DSG® 25

View Details

MS 4.3 C

View Details

Pressure chamber of pressure type KSO-140-N-SF-R

View Details

Walk-through shotblasting machine with overhead conveyor of "UD", "UDP" series

View Details

Sandblasting machine ARPU-5022 for glass

View Details

Sandblasting machine APU-3015 for glass and mirror

View Details

Sandblasting machine APU-3522

View Details

Mechanised shot blasting chambers of GAKS-K-1 type

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions