Available for Import

Available for Import

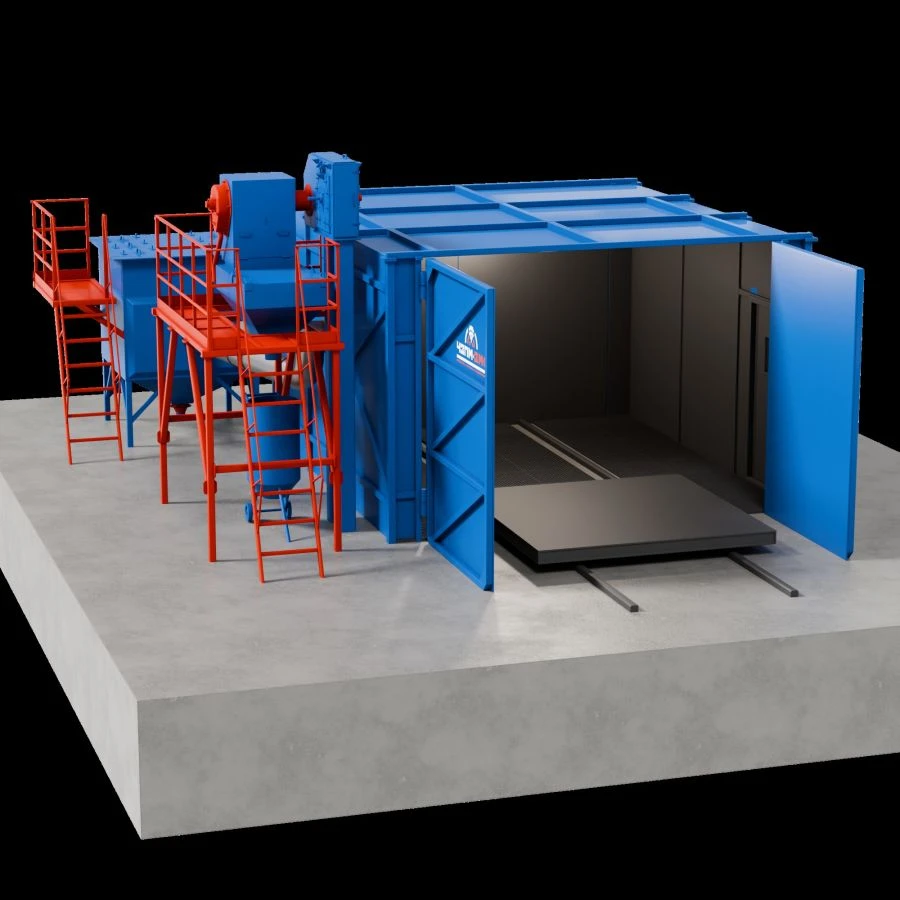

Inhabited blast cabinet Model OCDO

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

An inhabited blast chamber is designed for cleaning products of different sizes and shapes from rust and scale. The unit consists of a chamber, trolley, shot collection and feeding system, maintenance frame, ventilation system and control cabinet. The frame of the chamber is a frame structure connected by supporting elements fastened to each other. The chamber body is sheathed with sandwich panels 50mm thick. For protection, the walls and gates of the chamber are covered with rubber curtains (black colour) 2-3mm thick.Working principle: the processed product is placed on a trolley manually or by crane. The trolley is fed into the chamber. One or several operators blast the product. The shot with scale after the treatment of the product under its own weight falls through the grate deck on the longitudinal scraper conveyor, transporting it to the transverse screw conveyor.

Specifications

Cart with electric drive

1...10 t

LED luminaires

5...20 pc

Shot collection system

12...50

separator

Capacity1000kg/h Flow rate2~3m/sec.

Bucket elevator

Payload capacity 1000kg/h Power 1,2 kW

Blasting machine with operator's PPE kit

Number of posts, pcs.1 Capacity for shot200 litres Capacity up to 20 m2/hour Compressed air flow rate3,5 - 20,0 m/min.

Roughness of workpiece surface (achieved by selection of used shot)

Ra12.5~50m

Surface of the workpiece after cleaning (achieved by selection of the used shot)

Class A-B Sa2.5

Overall dimensions of the inhabited chamber on the inner perimeter, (WD), mm

5000 x 4500 x 3000 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Installation of hydro-abrasive treatment (cleaning) "KS-150"

View Details

Pressure blast machine VMZ®DSG® 25

View Details

Set for equipment of abrasive blasting area with vacuum system of transport and recovery of abrasive ma

View Details

Sandblasting machine APU-3015 for glass and mirror

View Details

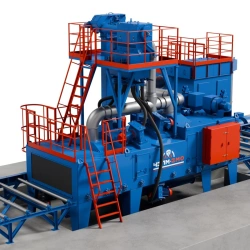

Pass-through type shotblasting machine DPU

View Details

Vacuum system for abrasive collection and recovery PSB 4/2

View Details

MS 4.3 C

View Details

Metal-jet apparatus model AMK1

View Details

Sandblasting machine ARPU-5022 for glass

View Details

Installation of hydro-abrasive treatment (cleaning) "KS-100"

View Details

Injector-type chamber KSO-110-I-SF-R

View Details

Mechanised shot blasting chambers of GAKS-K-1 type

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions