Available for Import

Available for Import

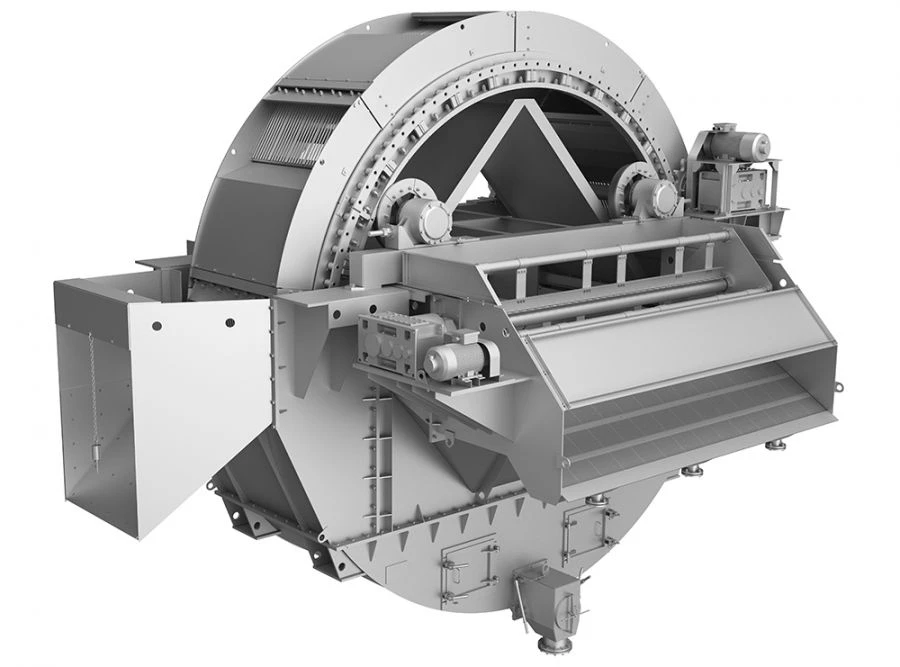

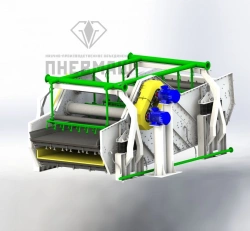

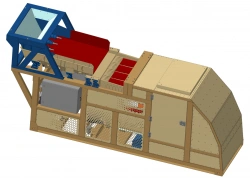

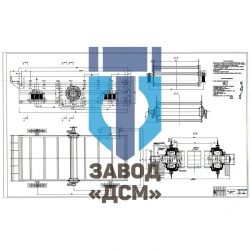

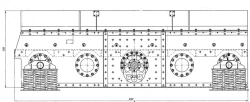

Heavy-medium wheel separator STK-4000

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

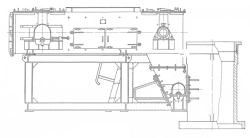

Heavy-medium wheel separator is designed for wet preparation of coal, anthracite and oil shale in heavy media with separation into two products - concentrate and preparation waste.

The separator is loaded through the receiver evenly across the entire width of the bath. The separator bath separates the feed material into two products. The material having a density lower than the density of the suspension floats, is transported by the suspension flow along the bath to the discharge threshold and is discharged from the bath by the blades of the rowing mechanism (beneficiation product). The material having density higher than the slurry density sinks to the bottom of the bath, falls into the buckets of the elevator wheel and is removed from the separator through the discharge chute (beneficiation waste).

When the elevator wheel rotates, the blades rotate under the action of their own mass, allowing the drowned product to be loaded into the bucket at the bottom of the bath and discharged from it at the top in the discharge zone.

The separator is loaded through the receiver evenly across the entire width of the bath. The separator bath separates the feed material into two products. The material having a density lower than the density of the suspension floats, is transported by the suspension flow along the bath to the discharge threshold and is discharged from the bath by the blades of the rowing mechanism (beneficiation product). The material having density higher than the slurry density sinks to the bottom of the bath, falls into the buckets of the elevator wheel and is removed from the separator through the discharge chute (beneficiation waste).

When the elevator wheel rotates, the blades rotate under the action of their own mass, allowing the drowned product to be loaded into the bucket at the bottom of the bath and discharged from it at the top in the discharge zone.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

CJF series classifiers

View Details

Bucket sampler (PK1)

View Details

Loading device for dryer pipes UZT2-11K

View Details

Heavy inertial screen GDSMT-42 (GIT-42)

View Details

SML Series Screens and their modifications

View Details

Installation for distribution of dry mixtures to be installed in the car body Bastion RCC

View Details

Energy dispersive fluorescent separator (ESP 4.154)

View Details

Lightweight inertial screen GDSML-63 (GIL-63)

View Details

Loading device for UZT2-9K dryer pipes

View Details

GIT-71 heavy duty inertial type screen

View Details

Automatic sampler (AO1-08)

View Details

Light Inertial Screen GDSML-42 (GIL-42)

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions