Available for Import

Available for Import

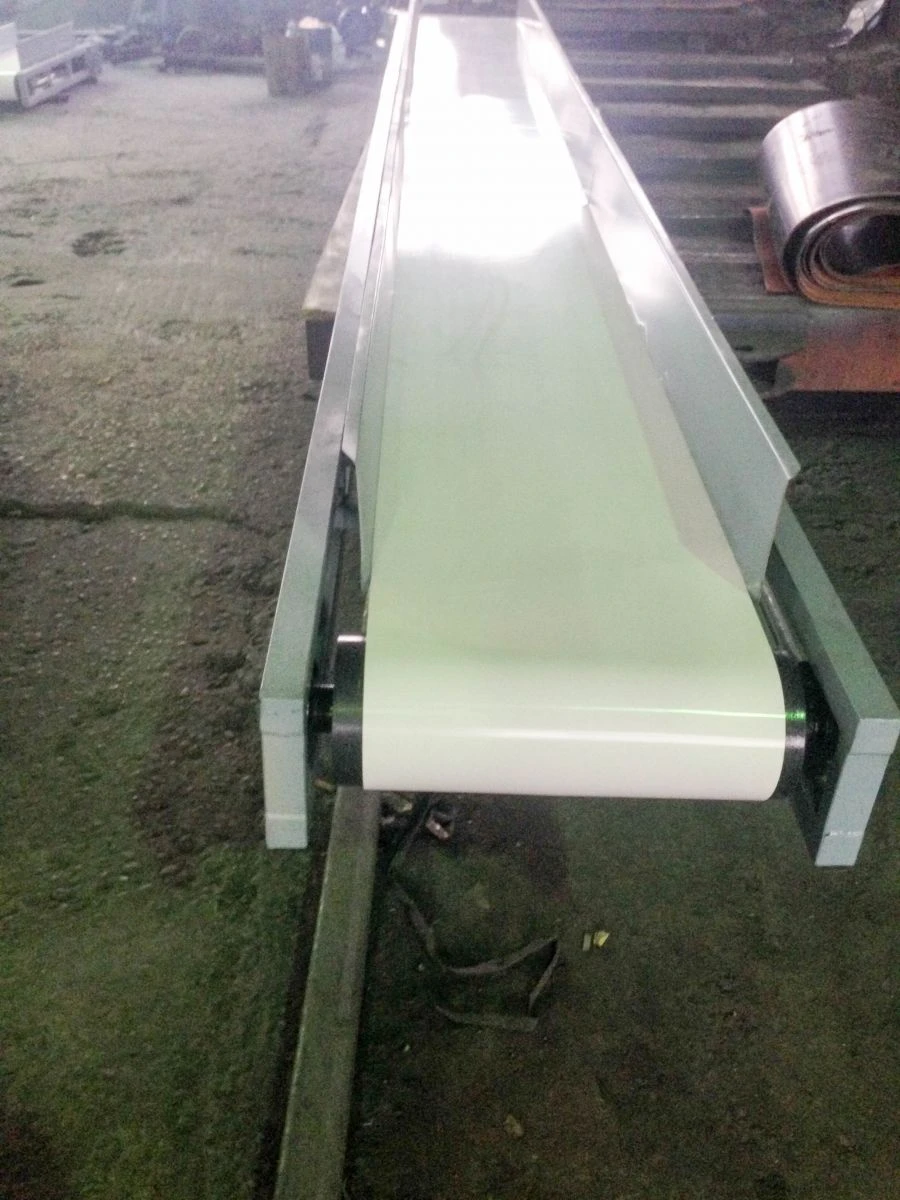

Food processing belt conveyor TC series model TC-1200-U

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Available Models

Description

Conveyor belt series TC is designed to move oilseeds, grain and grain products and other bulk goods at an angle of up to 5 degrees.

Conveyor is a stationary conveying device of continuous action with a working traction organ: - conveyor belt moving on rollers.

The device of the belt conveyor.

- Drive station is a frame of welded construction from angle steel, on the frame mounted drive drum, motor-reducer and clutch.

- The tensioning station is a welded frame made of angle steel. On the frame are mounted: tension drum with screw tensioning device; receiving tray with rubberised aprons attached to the bottom.

- The middle and inclined sections of welded construction are made of angles. They have holes at the edges for fastening between each other (as well as with the drive and tensioning stations). The sections are bolted together through strips.

- Conveyor roller supports are designed to support the load branch of the conveyor belt, to give it a grooved shape and to support the runaway branch.

Two straight and three grooved roller supports are installed on the middle and inclined sections.

Working principle of belt conveyor TC

When the drive station is switched on, the conveyor belt moves along the roller supports, transporting the load coming to it through the receiving chute of the tensioning station. Product discharge takes place on the belt turning round the drive drum. Loading of the conveyor is performed by loading units installed in a chain with the conveyor.

The total length of the conveyor depends on the number of middle sections installed in the line.

Conveyor is a stationary conveying device of continuous action with a working traction organ: - conveyor belt moving on rollers.

The device of the belt conveyor.

- Drive station is a frame of welded construction from angle steel, on the frame mounted drive drum, motor-reducer and clutch.

- The tensioning station is a welded frame made of angle steel. On the frame are mounted: tension drum with screw tensioning device; receiving tray with rubberised aprons attached to the bottom.

- The middle and inclined sections of welded construction are made of angles. They have holes at the edges for fastening between each other (as well as with the drive and tensioning stations). The sections are bolted together through strips.

- Conveyor roller supports are designed to support the load branch of the conveyor belt, to give it a grooved shape and to support the runaway branch.

Two straight and three grooved roller supports are installed on the middle and inclined sections.

Working principle of belt conveyor TC

When the drive station is switched on, the conveyor belt moves along the roller supports, transporting the load coming to it through the receiving chute of the tensioning station. Product discharge takes place on the belt turning round the drive drum. Loading of the conveyor is performed by loading units installed in a chain with the conveyor.

The total length of the conveyor depends on the number of middle sections installed in the line.

Specifications

Type of product according to PP RF 616

Belt conveyors

Belt width

1200 mm

Type of conveyor

Stationary

Capacity, per hour

1200

Average service life, at least

10 a

Conveyor length

5...25 m

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Belt conveyor for food industry KLP series model KLP-650-U

View Details

Belt conveyor TL-1000 length 133 m capacity 350 t/h

View Details

Belt conveyors of RT-TVL brand

View Details

Belt conveyor TLN-700. 220

View Details

Belt conveyor type B

View Details

Conveyor conveyor of conveyor brand G4-TK-1,2-1,5P

View Details

Belt conveyors ??? ( ????) 2000

View Details

Belt conveyor

View Details

Belt conveyor reversible TLR-1200. 1100

View Details

Belt conveyor KL-S650-175-35 (175 t/h) 35 m

View Details

Stationary belt conveyor model TBS modification TBS-50 (rollerless)

View Details

Belt conveyor type KL(P)

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions