Available for Import

Available for Import

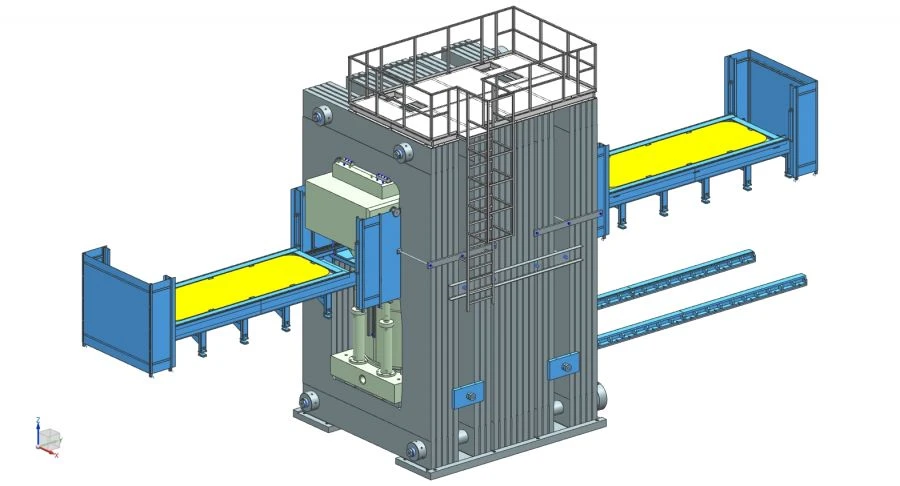

Elastic cushion stamping press model P5200 with force 200MN

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Stamping by elastic medium is a progressive method of sheet metal forming. As a result of such stamping, parts of high precision are obtained.

The main working organ in the presses of elastic medium stamping is a polyurethane pad placed in a container with an open bottom side. The stamping tooling together with the workpiece is "squeezed" into the cushion with a force that causes the elastic cushion to deform and "crimp" the workpiece on the tooling, thus the sheet blank acquires the shape of the surface of the mould on which it is placed. The "crushing" of the tooling with the workpiece into the cushion takes place by means of hydraulic cylinders, which are installed under the working table and when the high-pressure working fluid is fed into the cylinders, the table moves upwards.

The main working organ in the presses of elastic medium stamping is a polyurethane pad placed in a container with an open bottom side. The stamping tooling together with the workpiece is "squeezed" into the cushion with a force that causes the elastic cushion to deform and "crimp" the workpiece on the tooling, thus the sheet blank acquires the shape of the surface of the mould on which it is placed. The "crushing" of the tooling with the workpiece into the cushion takes place by means of hydraulic cylinders, which are installed under the working table and when the high-pressure working fluid is fed into the cylinders, the table moves upwards.

Specifications

Type of product according to PP RF 616

Hydraulic presses

Effort

20000000...200000000

Maximum container pressure

40 MPa

Highest height of the part to be stamped

270 mm

Length of the table working surface

4200 mm

Width of the table working surface

1300 mm

Polyurethane cushion thickness

600 mm

Number of tables for mold presses

2 pc

Distance from the bottom plane of the container to the table plane

300 mm

Installed capacity

411 kW

Operating pressure of high-pressure pumps

25 MPa

Operating pressure of low pressure pumps

10 MPa

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Model P5240-LShP-04 Elastic Cushion Press with 240MPH force

View Details

Hydraulic press for crimping cable lugs and sleeves, model PP-NA16300

View Details

Hydraulic press of plunger design DE 2428 (DG 2428)

View Details

Sling washer, model: PS200C

View Details

CNC hydraulic press brake STS 20/510 series

View Details

Hydraulic press with C-shaped bed PB6324

View Details

Containerised shear press CPS-400

View Details

Hydraulic press for pressing lugs, sleeves and hardware clamps, model ???12300

View Details

STL-3 Hydraulic CNC press brake KLASSIK STS 1000/10200

View Details

25t P6324B single column hydraulic press with individual drive.

View Details

Hydraulic press of plunger version DE 2434

View Details

630kN hydraulic press, model P6328B

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions