Available for Import

Available for Import

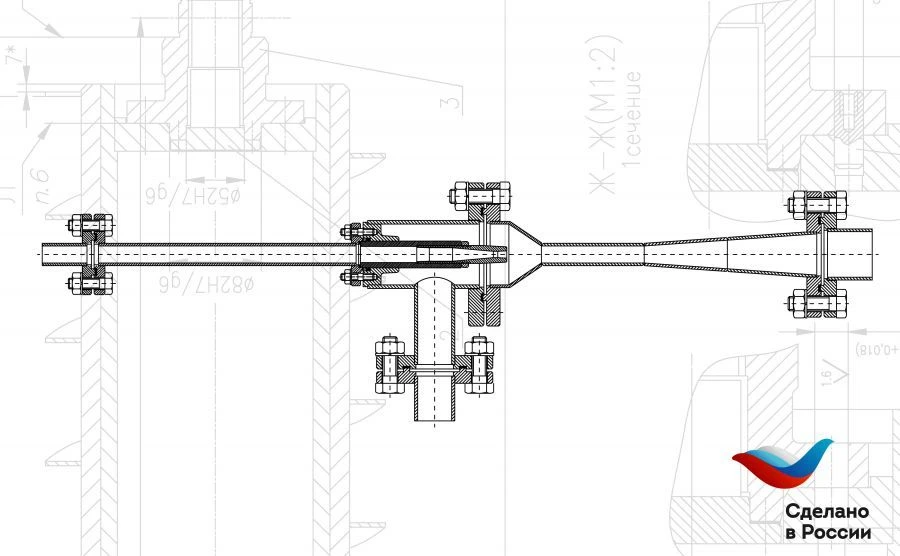

Ejector

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Ejectors are devices that transfer kinetic energy from one medium travelling at a higher velocity to another.

Working according to Bernoulli's law, ejectors create in the narrowing section of the reduced pressure of one medium, which causes suction into the flow of another medium, which is then carried away and removed from the place of suction by the energy of the first medium.

Steam ejectors are jet apparatuses for sucking gases from a confined space and maintaining rarefaction.

The working steam enters the nozzle, where it expands to a pressure value equal to the pressure in the suction chamber and acquires a high velocity.

The working steam jet flowing out of the nozzle captures the vapour-air mixture injected into the ejector receiving chamber from the condenser and enters with it into the narrowing part of the diffuser or mixing chamber.

The latter consists of a conical part and a cylindrical section.

In the mixing chamber, including the cylindrical section, velocity equalisation across the flow cross-section takes place, accompanied ...

Working according to Bernoulli's law, ejectors create in the narrowing section of the reduced pressure of one medium, which causes suction into the flow of another medium, which is then carried away and removed from the place of suction by the energy of the first medium.

Steam ejectors are jet apparatuses for sucking gases from a confined space and maintaining rarefaction.

The working steam enters the nozzle, where it expands to a pressure value equal to the pressure in the suction chamber and acquires a high velocity.

The working steam jet flowing out of the nozzle captures the vapour-air mixture injected into the ejector receiving chamber from the condenser and enters with it into the narrowing part of the diffuser or mixing chamber.

The latter consists of a conical part and a cylindrical section.

In the mixing chamber, including the cylindrical section, velocity equalisation across the flow cross-section takes place, accompanied ...

Specifications

Main construction material

stainless steel

Compressed steam pressure

15 MPa

Ejected vapour pressure

B1/B8 2100/900 MHz MPa

Working steam pressure

5 MPa

Compressed vapour temperature

120 °C

Temperature of ejected vapour

Flat grinder, Specialised grinder °C

Working steam temperature

85 °C

Operating medium

vapours of syrupy alcohol, water vapours

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Steam-water process washing PVTM PRETOR-37

View Details

Disinfection-shower unit DDP-2M (in trailers)

View Details

Disinfection unit DA-10M on chassis of two-axle trailer model 849181.

View Details

Disinfection unit DA-10

View Details

K.Shl.IZO.03.X-BIO Disinfection mobile chamber

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions