Available for Import

Available for Import

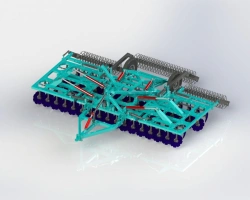

Double row disc harrow trailed disc harrow of the BDM series model BPM-2,4x2

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Available Models

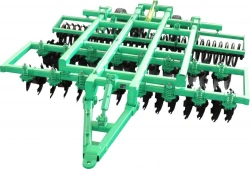

Double row disc harrow trailed folding disc harrow PM series model BDS-7,5x2

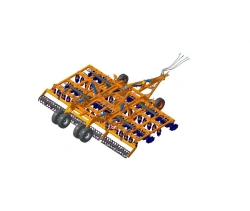

Double row disc harrow with elastomer folding Cortes BDM series model BENS-5x2

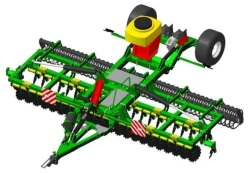

Double row disc harrow mounted on elastomers Badger BDM series model BELN-1,8x2

Two-row mounted disc harrow BDM model BDN-2,4x2

Double row trailed disc harrow BDM series model BAM-4,5x2

Description

Two-row modernised disc harrow BDM with a bearing unit inside the disc sphere, with discs on an individual stand, with changing the angle of attack of discs synchronously in each row, is designed for surface tillage to a depth of 15cm, weed killing and shredding crop residues. Due to uniform mixing of earth with crop residues, the disc harrow is effective on soils subject to wind and water erosion. Plant residues, evenly mixed with the topsoil, protect the soil from blowing out and leaching and improve air exchange. At the same time, plant residues in the ground are actively transformed into humus, increasing soil fertility.

The main advantages of 2-row BDM harrows in comparison with 3- and 4-row implements:

- The distance between discs in a row at two-row harrows 300mm, the distance between rows of discs 1000mm. Disc overlap is not complete in double rows. Spaces between discs are processed by tearing off and displacement of earth by the disc of the second row into the furrow formed by the disc of the first row. This does not always happen. However, with the second pass diagonally to the first, the field is processed perfectly: the faults of the first pass are cut off and the ridges on the bottom are cut off. And since the working width of twin-row implements is larger with the same number of discs, their productivity is higher and fuel consumption per cultivated area is lower.

- The length of twin-row implements is much shorter. Therefore, twin-row implements are more manoeuvrable and have smaller swaths. For the same reason there are a lot of mounted implements among twin-row implements - less load on the tractor linkage. Mounted twin-row implements are much cheaper, simpler and more manoeuvrable than trailed implements.

- Due to the smaller distance between discs in a row, the passability of double row implements on a clogged field and in high humidity is less than that of 3- and 4-row implements. However, for the same reason, the field surface is less ridged after the twin rows have passed. That is why it is better to use the twin rows at a shallower depth, for timely cultivation in fields with low weediness and for pre-sowing cultivation.

- The use of angle of attack adjustment makes the BDM twin-row harrow the most versatile implement. By increasing the angle of attack and at a relatively low speed, it is possible to cultivate the field deep enough without any faults. With decreasing angle of attack and at high speeds, the field can be cultivated to a shallow depth and in two passes immediately under sowing.

The main advantages of 2-row BDM harrows in comparison with 3- and 4-row implements:

- The distance between discs in a row at two-row harrows 300mm, the distance between rows of discs 1000mm. Disc overlap is not complete in double rows. Spaces between discs are processed by tearing off and displacement of earth by the disc of the second row into the furrow formed by the disc of the first row. This does not always happen. However, with the second pass diagonally to the first, the field is processed perfectly: the faults of the first pass are cut off and the ridges on the bottom are cut off. And since the working width of twin-row implements is larger with the same number of discs, their productivity is higher and fuel consumption per cultivated area is lower.

- The length of twin-row implements is much shorter. Therefore, twin-row implements are more manoeuvrable and have smaller swaths. For the same reason there are a lot of mounted implements among twin-row implements - less load on the tractor linkage. Mounted twin-row implements are much cheaper, simpler and more manoeuvrable than trailed implements.

- Due to the smaller distance between discs in a row, the passability of double row implements on a clogged field and in high humidity is less than that of 3- and 4-row implements. However, for the same reason, the field surface is less ridged after the twin rows have passed. That is why it is better to use the twin rows at a shallower depth, for timely cultivation in fields with low weediness and for pre-sowing cultivation.

- The use of angle of attack adjustment makes the BDM twin-row harrow the most versatile implement. By increasing the angle of attack and at a relatively low speed, it is possible to cultivate the field deep enough without any faults. With decreasing angle of attack and at high speeds, the field can be cultivated to a shallow depth and in two passes immediately under sowing.

Specifications

Type of product according to PP RF 616

Disc harrows

Working width

2.4 m

Transport width

2.9 m

Depth of treatment, up to

10...18 cm

Disk diameter

460...610 mm

Number of disks

16 pc

Angle of attack of the disks

15...25

Tractor power, from

80

Operating speed, up to

15

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

AGL-4 disc harrow

View Details

Folding BDM-7x4P disc harrow (Sura-7x4P sll.).

View Details

Tandem disc harrow DX-850/970

View Details

BD 5,0x3PG disc harrow with roller

View Details

Heavy disc harrow BDK-3,0M

View Details

Modernised Diaz disc harrow BDM-7x4PK-ShKS

View Details

Modular disc harrow BDM-3,2x2H

View Details

3,0x2H mounted disc harrow with roller

View Details

Catros 3001 disc harrow with harrow bar

View Details

Modular disc harrow BDM-7x4-09

View Details

Modular disc harrow PM-6x2

View Details

Trailed disc harrow BDP-5,2.EU.00.00 TU

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions