Available for Import

Available for Import

Contact welding machine MT-4022 UHL4

Manufacturer:

ESVA OJSC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

The machine is designed specifically for welding light alloys, but also, allows high-quality welding of stainless steels, brass and bronze parts.

MAIN FEATURES:

- The force drive is based on standard linear rolling roller guides, which ensures minimum friction losses. This type of drive provides high quality welding;

- The three-chamber pneumatic cylinder allows smooth adjustment of the solution, creating a variable force before or during welding, providing forging force;

- Straight-line electrode stroke;

- Stabilisation system of the welding current in case of fluctuations of the mains voltage;

- Efficient pneumatic compression drive system with compressed air regulation and preparation system;

- Water cooling system for transformer and electrode holders;

- Noise silencers on pneumatic valves.

MAIN FEATURES:

- The force drive is based on standard linear rolling roller guides, which ensures minimum friction losses. This type of drive provides high quality welding;

- The three-chamber pneumatic cylinder allows smooth adjustment of the solution, creating a variable force before or during welding, providing forging force;

- Straight-line electrode stroke;

- Stabilisation system of the welding current in case of fluctuations of the mains voltage;

- Efficient pneumatic compression drive system with compressed air regulation and preparation system;

- Water cooling system for transformer and electrode holders;

- Noise silencers on pneumatic valves.

Specifications

Type of product according to PP RF 616

Contact welding equipment

Operating voltage

380 V

Mains frequency

SBVVBG

Contact welding

Designed for welding of light alloys, but also, allows qualitatively weld stainless steels, parts of brass and bronze.

Highest secondary current, kA

40

Rated continuous secondary current

11

Highest short-circuit power, kVA

400

Nominal (longest, shortest) outreach

500 mm

Nominal-maximum solution

150 mm

Overall dimensions (DxWxH)

(1350x525x2290) mm

Weight

860 kg

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Ferrous Metal Welding Rotator for Heavy-Duty Applications

View Details

Inverter Rectifier with Feeding Mechanism for Mechanized Arc Welding S3 SpeedPulse XT

View Details

High-Temperature Contact Soldering Unit PKV "Mendeleevets" with Additional Equipment

View Details

Ural-Master 300 Rectifier for Manual Arc Welding

View Details

Contact Spot Welding Machine for Metals and Alloys, Thickness 0.01 to 1.20 mm - Chastota-6

View Details

Industrial Inverter Welding Machine for Manual and Semi-Automatic Welding - ROSWELD MIG 350

View Details

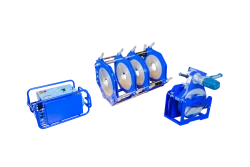

Polymer Pipe Butt Welding Machine SSPT 160 E

View Details

MTK-2002 Contact Welding Machine for Precision Metal Joining

View Details

Polymer Pipe Butt Welding Machine SSPT 315 E

View Details

Inverter Power Supply for Welding MS-351MX

View Details

Portable Welding Machine BSG-250 U1

View Details

Wire Feeding Mechanism MPO-31MH for MS-351/501MH

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions