Available for Import

Available for Import

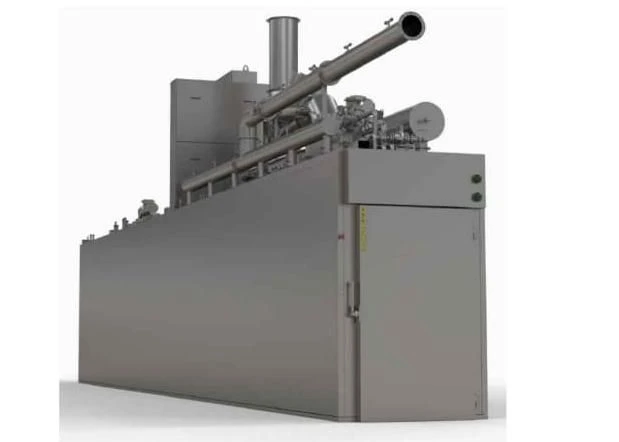

Combined heat treatment chamber NEWTERM

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Description

Combined chamber "NEWTERM" for heat treatment is designed for smoking, cooking meat and meat products and their subsequent cooling and consists of a smoking chamber "NEWTERM" with steam heating and intensive cooling chamber "NEWTERM" heat carrier "ECO-TEN-NV-30" (refrigerant glycol), combined in one tunnel with a system of automatic frame feeding, in a pass-through version.

Connection of chambers into one equipment reduces the total processing time, saves most of the manual manipulations with heavy carts, reduces the weight loss of the product compared to the use of separate chambers. The transport system will semi-automatically load the carts into the first section, after heat treatment they will be automatically reloaded into the second section, after cooling they will be semi-automatically unloaded from the second section. While the product is cooling in the second section, the heat treatment of the next batch can be carried out in the first section.

Connection of chambers into one equipment reduces the total processing time, saves most of the manual manipulations with heavy carts, reduces the weight loss of the product compared to the use of separate chambers. The transport system will semi-automatically load the carts into the first section, after heat treatment they will be automatically reloaded into the second section, after cooling they will be semi-automatically unloaded from the second section. While the product is cooling in the second section, the heat treatment of the next batch can be carried out in the first section.

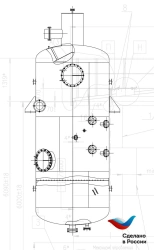

Specifications

Height

2000 mm

Length (depth)

1010 mm

Width

1000 mm

Material

stainless steel AISI 304

Chamber floor thickness

4 mm

Maximum temperature during heat treatment

105...110 °C

Cooling to the temperature in the center of the product

6 °C

Dimensions

1000*1010*2000 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Handwashbasin, RMNN series, model RMNN.

View Details

Boiler cooking fodder brand KVK working volume of 8.5 cubic metres.

View Details

Vacuum evaporator heater 4000

View Details

Weighing dosing module, MDV 21 series (with pneumatic buckets)

View Details

MRS series hand sinks

View Details

System of supply and distribution of product pipelines of evaporator plants (distribution comb of product and process lines)

View Details

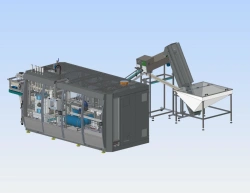

PET container blowing machine model A-4000-4

View Details

Sectional insert, modularised VSM

View Details

Sharpening machine for cutter knives DVAK SZK-04U

View Details

Vacuum sweetener (evaporator) ISPO

View Details

PET container blowing machine model A-2000 F-4

View Details

Washing bath with working surface, series VMRB-2 model VMRB-2-U.

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions