Available for Import

Available for Import

Bucket belt bucket elevator of NCC model modification 2NTsK-175-2

Manufacturer:

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Key Highlights

- Made in Russia - engineered for durability

- Suitable for challenging environments

- Lower cost of ownership than European alternatives

- Bulk orders available with volume discounts

- Documentation and customs clearance assistance provided

Available Models

Bucket belt bucket elevator of NCC model NCC-10-2 modification

Bucket belt bucket elevator of NCC model NCC-5 modification

Bucket belt bucket elevator of NCC model NCC-10 modification

Bucket belt bucket elevator of NCC model NCC-350-2 modification

Bucket belt bucket elevator model NCCK modification 2NTsK-5-2

Description

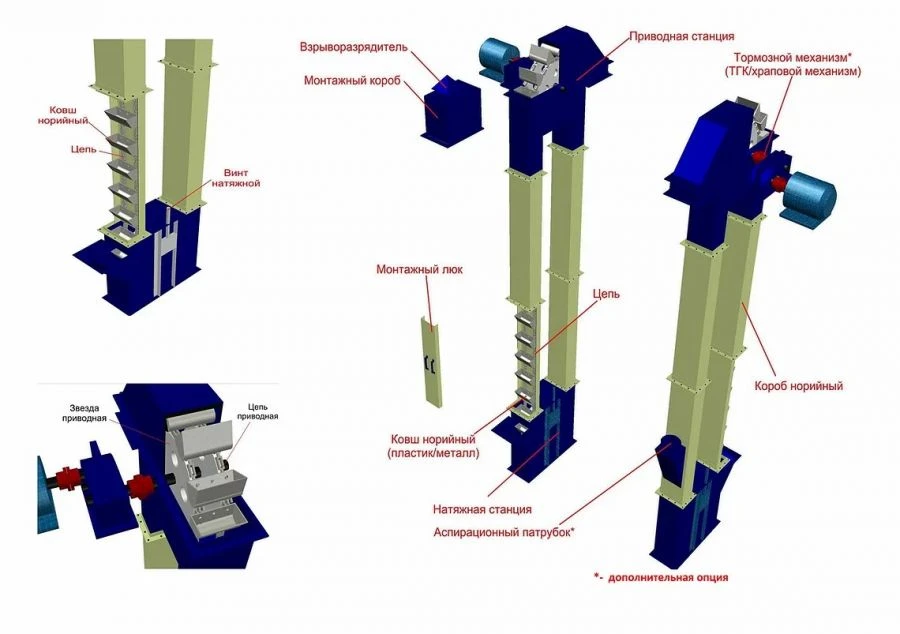

Noria (elevator) is a vertical bucket conveyor designed to move bulk, lumpy and liquid goods. The main traction organ is a set drive sprocket with milling for chain links. The elevator layout, regardless of its design, consists of two main elements and a set of intermediate elements. The main parts of the elevator are the upper part ("head" or drive station) and the lower part ("shoe" or tensioning station). The "head" contains the drive drum with gearmotor and elevator brake, as well as a platform for elevator maintenance. The "shoe" is a tensioning station with an idle drum and inspection hatches for visual inspection of the elevator. Intermediate sections are welded boxes made of thin sheet metal reinforced with angles. In some cases the end walls can be made of technical rubber, which enables easier removal of adhering cargo.

Depending on the customer's requirements, the burrow can be equipped with sensor systems. The standard package includes back pressure, sliver run-off and sliver break sensors. The back-up sensor detects overfilling of the "shoe", which is caused by the load slipping past the load carrying buckets. The belt deflection sensor monitors the horizontal deflection of the belt in relation to the surface of the drive and tensioning drums, which is possible under high dynamic loads. The belt break sensor detects the moment of belt breakage in case of extreme wear and switches off the elevator drive. In order to prevent backward scrolling of the drum in case of belt breakage or drive station malfunction, there is an elevator brake - a special ratchet that prevents the elevator shaft from scrolling in the opposite direction.

Depending on the customer's requirements, the burrow can be equipped with sensor systems. The standard package includes back pressure, sliver run-off and sliver break sensors. The back-up sensor detects overfilling of the "shoe", which is caused by the load slipping past the load carrying buckets. The belt deflection sensor monitors the horizontal deflection of the belt in relation to the surface of the drive and tensioning drums, which is possible under high dynamic loads. The belt break sensor detects the moment of belt breakage in case of extreme wear and switches off the elevator drive. In order to prevent backward scrolling of the drum in case of belt breakage or drive station malfunction, there is an elevator brake - a special ratchet that prevents the elevator shaft from scrolling in the opposite direction.

Specifications

Capacity, per hour

2...175 t

Transport height

4...60

Bucket volume

0.55...6.2

Average service life, at least

6 a

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Bucket chain dipper for food processing NC series model NC-350-U

View Details

Grain elevator NZ-40A4-17 (40 tonnes per hour) 17m with left-hand drive arrangement

View Details

HL series food processing ladle belt bucket elevator, model 2xNL-50-U

View Details

Grain bucket elevator NZK-5 (8m)

View Details

Noria of UN type

View Details

Bucket elevator (noria) type NC-40

View Details

Vertical grain elevator type NV

View Details

Food processing belt bucket elevator NL series model NL-10-01

View Details

Grain elevator NZE-175A4-10,5 (175 tonnes/hour) 10,5m with right-hand drive arrangement

View Details

Bucket belt elevators for food industry (type II-175)

View Details

Bucket elevator (noria, type E, NB)

View Details

NM-350 type bucket elevator (noria)

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions